Product Assurance

Project engineers are focused on making their space missions operate as planned. But such an optimistic approach is insufficient in the face of Murphy's Law, the well-known maxim that was originally taken from rocketry: 'what can go wrong will go wrong.'

So to improve the likelihood of mission success, project teams are assisted by a separate class of personnel possessing a very different mindset.

ESA's Product Assurance and Safety (PA&S) engineers are responsible for failure-proofing missions by ensuring that the materials, mechanical parts, processes and electrical components used to assemble a spacecraft or launcher shall be fit for purpose over the entire life of a mission.

They do this by providing engineering support to all ESA activities, verifying compliance to Product Assurance requirements. They represent an independent technical authority in the materials, mechanical parts, processes and electrical component domains, while also providing bespoke space environmental exposure facilities for use in support of European programmes.

They also seek to secure the availability of qualified materials, parts, processes and personnel to all ESA missions, future-proofing them by guaranteeing short, medium and long-term access to critical technologies, monitoring industry trends across all technical domains to help underpin Europe's competitiveness in the space sector.

The emphasis here is on enabling technologies such as gallium nitride (GaN), MEMs, Micro- and Nano-Technology (MNT) and Deep Sub-Micron (DSM), along with the growth in European component availability driven by the European Components Initiative (ECI).

PA&S engineers are also tasked with establishing and implementing requirements and standards for the development and procurement of space-grade materials, components and related processes – maintaining Europe’s standards for space. These ensure consistency and agreement across the entire space sector in the quality of European products.

Space projects rely on embedded PA&S engineers to ensure hardware and software quality, product reliability, electronic components, standards, materials, mechanical parts, critical industrial fabrication processes and configuration control.

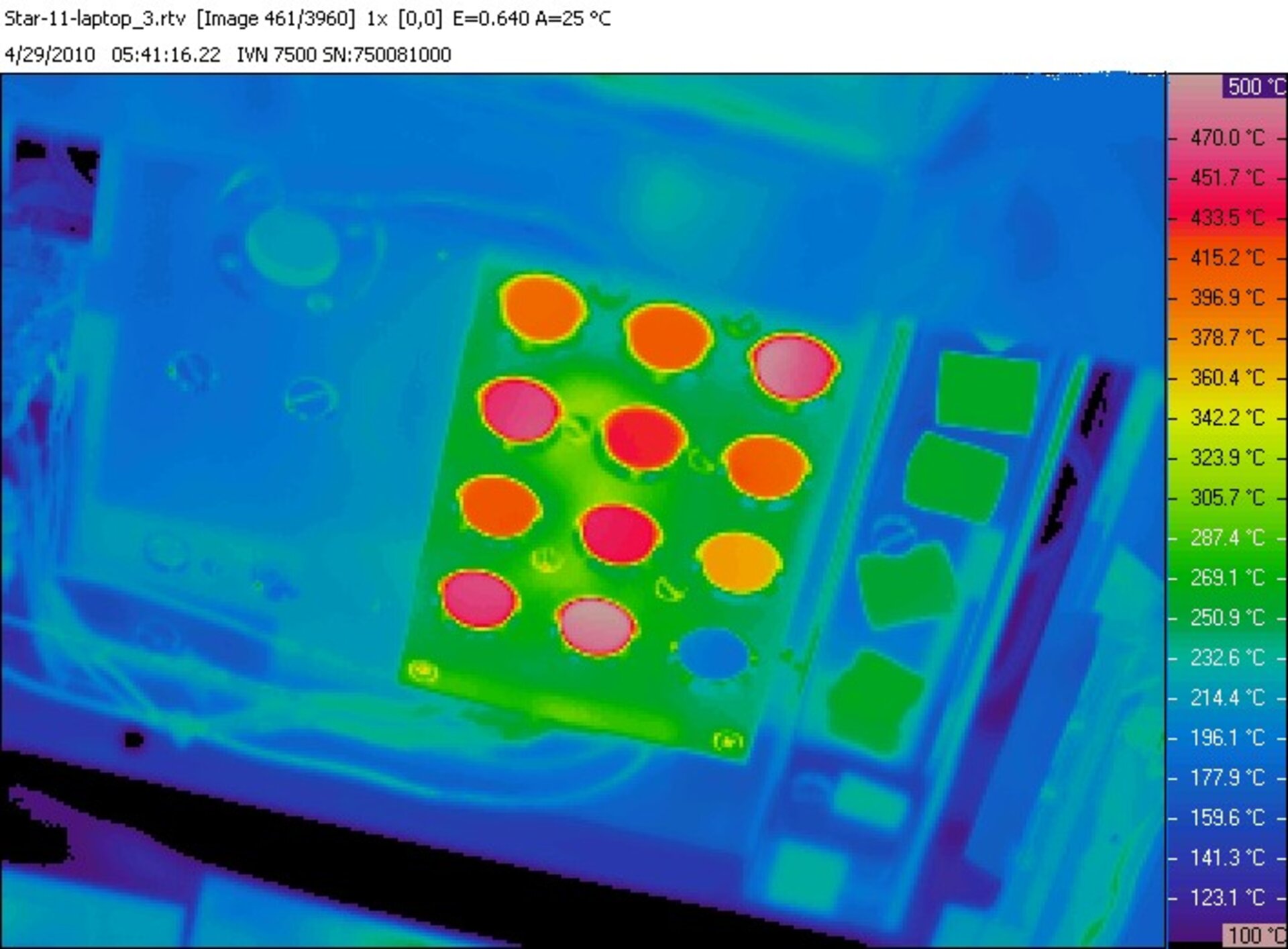

Their aim is to develop and promote a technical understanding of the effects of the space environment on materials and components. Their working tools are laboratories, test facilities, reviews, audits, inspection of processes and products. PA&S engineers will alert managers if on potential quality problems and initiate corrective actions.