New Generation Short Wave Infra-Red (SWIR) Immersed Grating – Phase 1

| Programme: | GSTP | Achieved TRL: | 3 |

| Reference: | G511- 039MM | Closure: | 2016 |

| Contractor(s): | CSEM SA (CH) | ||

Spaceborne remote sensing of the chemical composition of the Earth’s atmosphere is an important monitoring tool for scientists studying the influence of gases on the climatic changes and the weather. The requirements of diffraction gratings used in such spaceborne spectrometers are permanently increasing in performance. Using conventional diffraction gratings would result in larger gratings, and consequently in bulkier instruments. Immersed gratings, especially immersed gratings in transmission, are technical solutions to achieve higher performance and more compact instrument configurations simultaneously.

Objectives

The objectives of this activity was to develop two immersed gratings, one in reflection and one in transmission, operating in the SWIR spectral range, by focusing on technology and process development to enable the manufacturing of the different gratings and to measure process effects and the resulting optical performances.

Benefits

The development of an immersed grating in transmission may provide higher efficiency and lower polarization sensitivity, with respect to an immersed grating in reflective configuration and state-of-the-art. In fact, a SWIR immersed grating operating in transmission may also generate less stray-light, allowing for better measurement of the depth of the absorption lines in highly resolved radiance spectra. Furthermore, it also offers the possibility of using a second prism bonded to the grating profile leading to simpler instrument designs.

Achievements and status

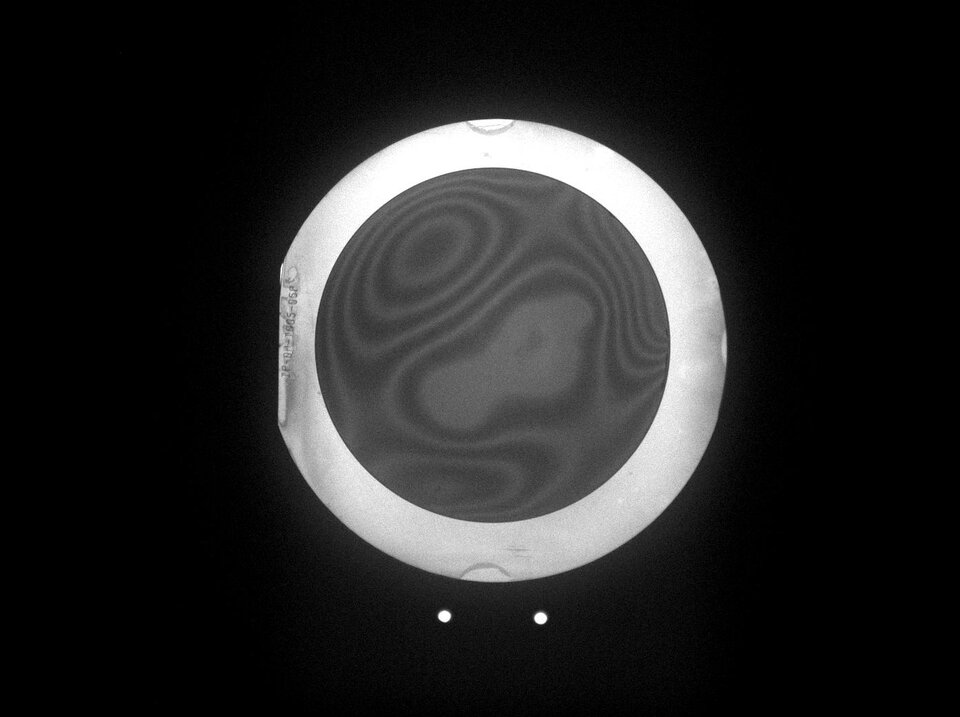

In the frame of this activity proof of concept was demonstrated and samples were developed, demonstrating very low sidewall roughness in the range of 3 nm RMS (root mean square). This was achieved by developing a new dry-etching, an improved masking process and by optimizing the polishing and cleaning methods.

Next steps

Based on these technology developments the manufacturing of SWIR immersed grating for space-borne spectrometers has come into reach and will be performed in the next phase of this activity where a full prototype will be built. Phase 2 also foresees the purchase of a bonding equipment to complete the silicon to silicon bonding development.