Silver in Space

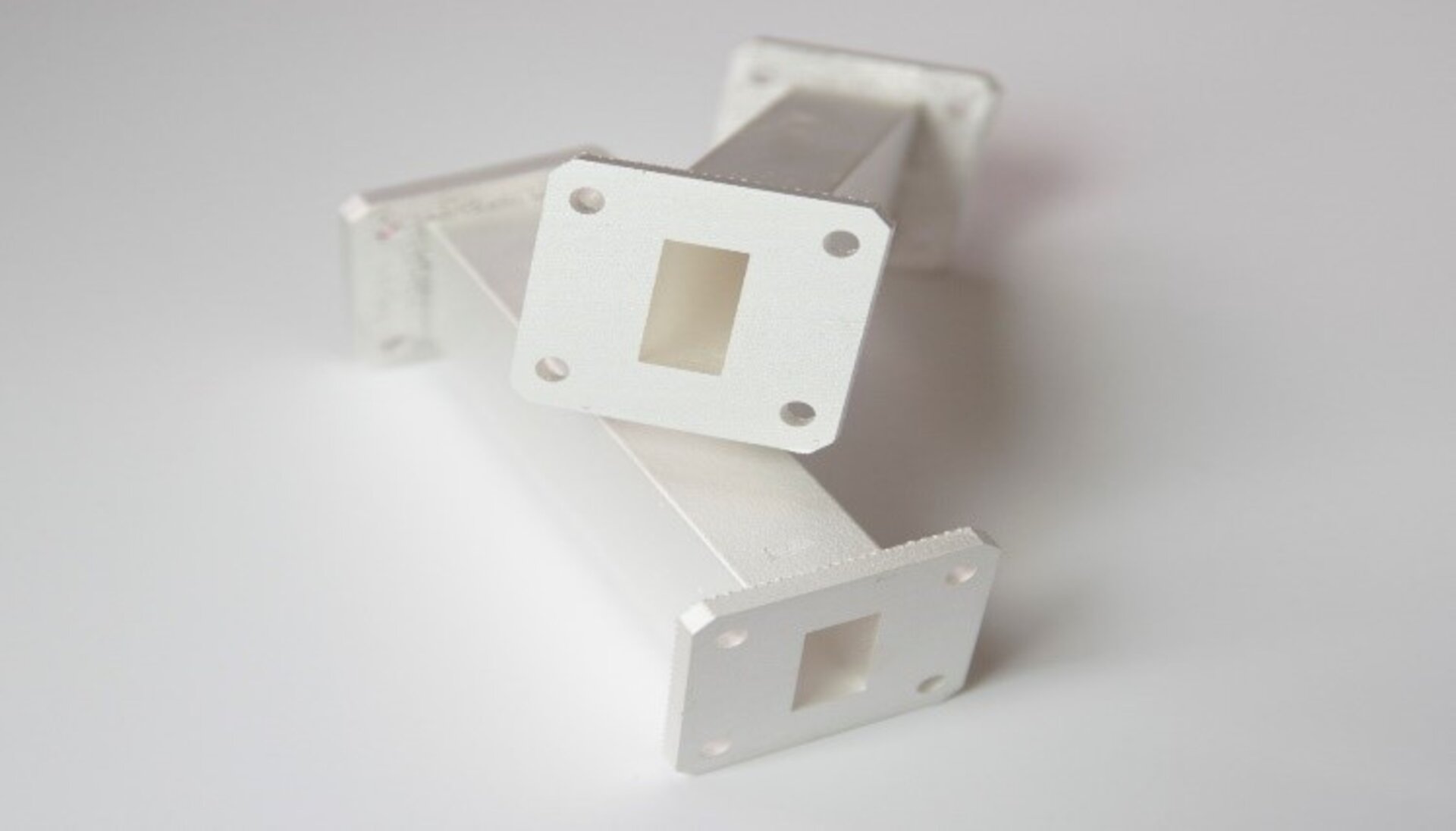

A GSTP contract with Sweden found that by combining 3D-printing of aluminium microwave components with autocatalytic silver plating it can reduce lead times and could enable more complex geometries to be designed

Autocatalytic Silver Immersion Gold is an alternative to electroplating and immersion processes and it has the potential to improve both performance and reduce plating costs.

Developed as a replacement for nickel as a surface finish for printed circuit boards, it has not been considered for Space until now. Since nickel-based coatings are known to suffer from quality issues, such as brittle intermetallics or black pad failures, silver plating microwave components instead could resolve this.

A GSTP contract with RISE IVF in Sweden combined 3D-printing of aluminium microwave components and autocatalytic silver plating and found that it can reduce lead times and plating could enable use of more complex geometries.

The activity found that using the autocatalytic silver immersion gold finish provided surfaces with good solderability even after exposure to two different soldering processes, and that the solder joints formed between various components had good reliability.

Furthermore, autocatalytic silver plated microwave components had an RF-performance similar to electroplated components and meet all space environment requirements, eliminates problems with brittle intermetallics or “ black pad “ failures and is especially well suited for high frequency applications – meaning a combination of 3D-printing of aluminium microwave components and autocatalytic silver plating is an interesting alternative for space applications.

The activity hopes to follow up with targeted applications in the telecommunications field.

GSTP contract 4000122510 was completed in December 2019.