Building from a kit is faster, smarter way to make small satellites

Call it the Lego method of spacecraft design: use a pre-designed kit of miniaturised, modular parts – all previously qualified for space - to assemble whatever satellite a given mission requires. That’s the way ESA’s NanoSat works, aimed at delivering smaller, cheaper but equally effective spacecraft.

At the moment no two ‘standard’ satellites are ever quite the same, which is one reason they are all so costly: each one is painstakingly put together from custom-designed structural segments and electrical and mechanical components.

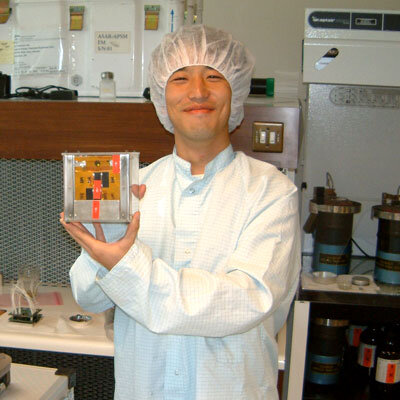

For the last two years the NanoSat project has pioneered a potentially game-changing model for small satellite construction, based on a set number of modular elements with standard interfaces to fit together in whatever configuration a spacecraft designer desires.

“We set out to see whether nanosatellites can be reliable platforms for truly useful payloads,” explained Stephen Airey of ESA's NanoSat project.

“This led us to devise a modular system allowing a very high amount of reuse of parts. They are manufactured on a large scale to reduce unit costs, and whatever type of satellite you need for a given mission, you can take these parts and quickly put it together.”

Stepping up from CubeSats

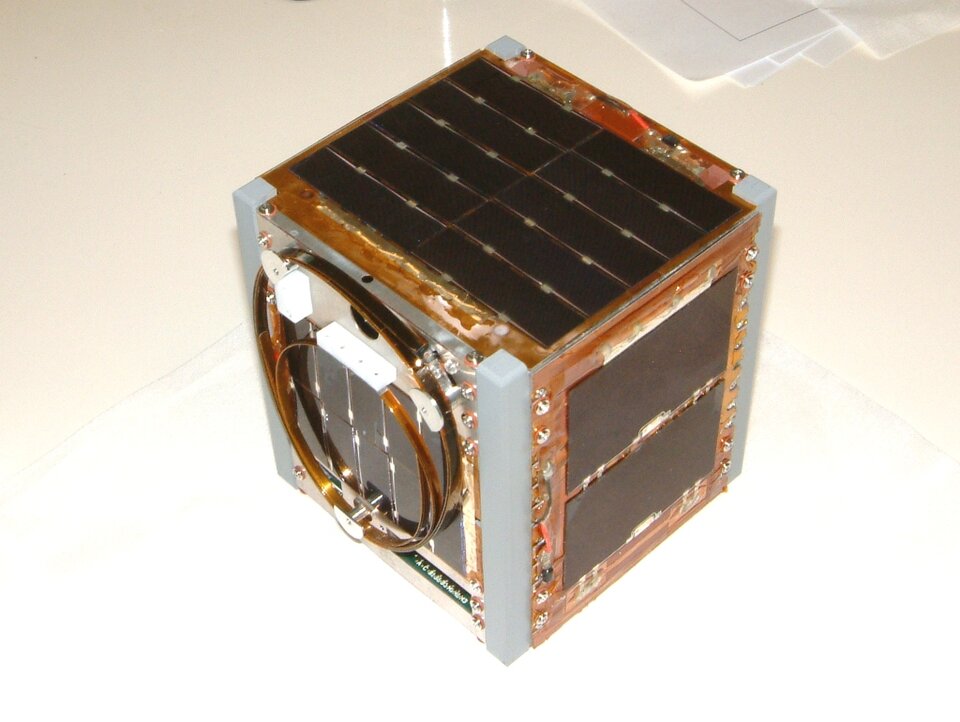

A basic modular system for satellites already exists on the smallest of scales. Invented by Bob Twiggs of Stanford University and Jordi Puig-Suari of California Poltechnic State University, CubeSats are 10cm x 10cm x 10cm satellites built to a standard kit-based design, allowing students and universities to fly their own payloads. The first CubeSats were launched in 2003 and 40 have flown to date.

“The inspiration for the modularity aspects of NanoSat comes partly from CubeSats," explained Mr Airey. “But CubeSats are primarily educational tools with limited payload capacity, functionality and reliability.

"For a 1-kg class mission you are talking webcam-type cameras, with only crude pointing capability and a lifetime measured in months because their commercial off-the-shelf electronics, a lack resistance to radiation and often non-existent propulsion capabilities.

“Instead we are applying the same modular system to the next size up, at which we believe we can do useful science. The aim is to be able to provide the equivalent payload capabilities as a current ESA satellite in the 300-500 kg class. Asking ourselves what was the smallest size that could still deliver something useful, we ended up at a platform mass of around 10 kg.

“That equates to nanosatellite class in the industry ranking, although this classification is a little misleading because it is strictly mass-based. As a result, a basic satellite consisting mainly of a lead block would be classed the same as our fully-capable satellite able to accurately point itself, propelling itself and possessing high mass memory and data downlink capability with a three-year lifetime.

In reaction we invented the term ‘Highly capable nano-satellite’ in order to be able to clearly differentiate our concept.”

| This article continues... |

|

| Next |

|