ATHENA thruster kicks off electrospray propulsion for NanoSatellites

Two new GSTP activities will take a technology from the 1970’s and turn it into a state-of-the-art propulsion system for combating the space debris problem.

Known as ATHENA (Adaptable THruster based on Electrospray powered by Nanotechnology), this new technology will be one of three developments in Europe pursuing novel electrospray propulsion as a way of moving small satellites in space.

Propulsion capabilities are necessary on all satellites so that they can be moved around, and especially once they reach the end of their life , or if they stop working, to push them out of orbit so they can safely re-enter the atmosphere and burn up, known as de-orbiting.

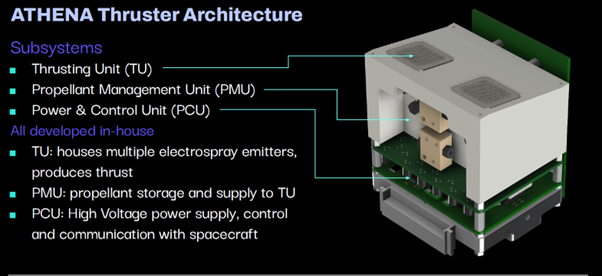

The innovative electrospray thrust system, built by IENAI SPACE in Spain, uses liquid salts as a propellant. These propellants are non-toxic and readily available since they’re already used for many different industrial applications Unlike many traditional electric propulsion systems, ATHENA is built to be extremely compact, making it ideal as space exploration trends towards smaller satellites or CubeSats.

A prototype of the technology has already flown in space aboard Firefly Alpha 2 but these new contracts with GSTP’s industry-led Element 2 and the De-Risk Framework will provide more than €1 million to look at the complete process of manufacturing and assembling the propulsion system and put it through ESA’s rigorous engineering tests to verify that it will survive and perform in the harsh environments of space for the entire lifespan of a mission.

Why do we need new, smaller propulsion systems?

65 years of space exploration has created a lot of space rubbish. One of the biggest problems ESA and the worldwide space community now face is how we handle the huge amount of old or broken satellites and launch stages floating around. This space debris poses a huge risk to future missions which might collide with it. There are a few things we can do with this debris and make space sustainable:

- We can monitor it, also called space situation awareness.

- We can limit the amount of traffic going into space.

- We can actively remove it from space.

- We can prevent more debris being created by helping satellites avoid collisions and to fall out of orbit once they’re at the end of their operational lifetimes.

The fourth option is the easiest and there are several TDE and GSTP activities currently running that will develop the necessary propulsion technology we need for future satellites to be able to maneuver and de-orbit safely.

Currently, there is a trend towards launching small satellites, called CubeSats, NanoSats or PicoSats which are measured in terms of Units. The basic unit, 1U, measures just 10 cm × 10 cm × 10 cm. Unlike larger satellites these often don’t have the space on board, or the power, to host powerful propulsion systems capable of pushing them out of orbit once they reach the end of their lives.

As more and more CubeSats are launched, even a tiny 1U CubeSat could create a space debris problem as just one collision creates tons more debris, each with its own risk of causing the next collision in a never-ending cascade.

Current technologies have not done well at scaling down to meet the small size or power available on these satellites and thus new inventions are needed to fill the gap. GSTP is currently funding activities which will make these propulsion systems more reliable, verified for space and suitable for anyone to use. ATHENA will be the only propulsion system on the market suitable for use on PicoSats, (satellites under 1kg in mass).

How will Athena work?

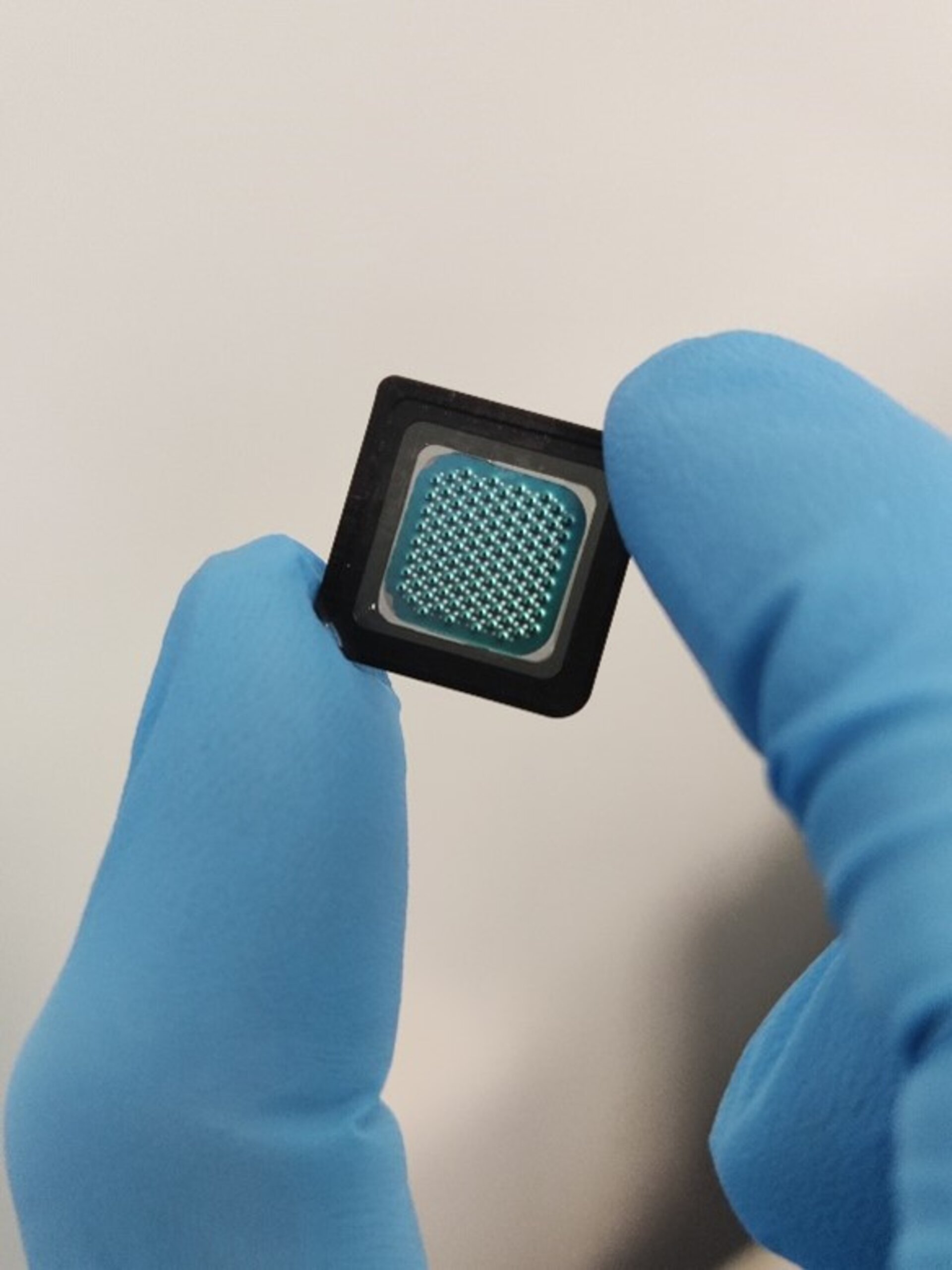

The ATHENA propulsion system works on the principle of electrospray thrust, where small particles from a propellant (in this case a liquid salt) move through a capillary and are accelerated between an emitter and an extractor operating at different electric potentials. The particles are then extracted in a way that makes them, essentially, spray out, at very high speeds (of the order of 20km/s), creating the force to move the satellite. Systems using this type of thrust not only have very small dimensions but they can also operate with very low power consumption and can be actively controlled to deliver tiny precise thrusts. They do pose some challenges, such as the difficult in fabricating a large array of emitters and performance stability across an entire satellite lifetime.

ATHENA is a scalable technology meaning it can grow to fit whatever a mission needs. On a 1U CubeSat it will be possible to fit up to eight emitters. This clustering means it can build and build to also serve larger propulsion systems; eventually the company intends to be able to fit larger ATHENAS on-board satellites up to 300kg in mass.

This customisation and modularity will be supported by a software IENAI SPACE have built alongside the propulsion system, which looks at all aspects of a mission and suggests which propulsion system and in which configuration would best suit it.

The GSTP activity will support IENAI SPACE in generating a process for making sure every custom thruster can be built in a reliable and robust way on the basis of precise engineering, preventing it from failing once in space.

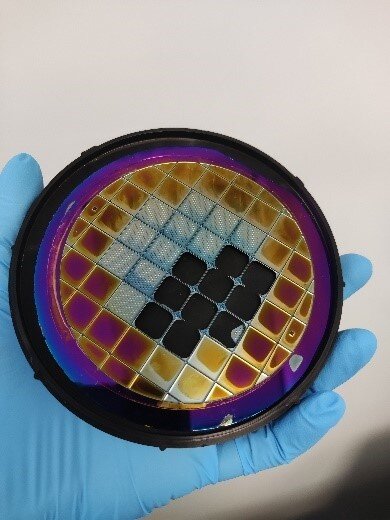

Microfabrication is at the core of the ATHENA technology and the team have already begun the process of patenting the way they manufacture the emitters. Their method allows the emitters to be manufactured very closely to the original design so the operating regime can be finely tuned to make it highly efficient.

How does Electrospray Electric Propulsion Work?

Athena will be one of just a handful of propulsion systems worldwide using this electrospray thrust technology.

Electrospray thrusters are very efficient at generating thrust, and need just a small amount of power. Unlike more traditional thrusters, most electrospray thrusters do not require the use of any pressurisation system and instead use passive or “semi-passive” propellant transport methods.

The thrusters extract charged particles from conductive liquids fed through small capillaries and emitters. These particles are then accelerated through small holes using an electrostatic field. In an electrospray thruster, the charged particles are able to be extracted due to the interaction between the liquid surface tension and the applied electrostatic force.

Depending on the type of thruster, the accelerated particles are either charged droplets or pure ions. Electrospray thrusters using ionic liquids as propellant, as ATHENA does, can emit ions of both polarities, meaning the spacecraft’s electric charge can also be balanced without a dedicated neutraliser. Individual electrospray emitters are often clustered together to form arrays in order to increase the emitting area and the produced thrust, at the cost of more power.

Liquid salt (ionic) propellants can be sensitive to humidity and oxidation, so precautions also have to be taken to minimise contamination risks from manufacturing, through test, and to launch.

The ATHENA project kicked off in March 2023 and expects to have a fully qualified product by the end of 2024.