Nano-materials can make lighter space components

Embedding carbon nano-materials in composite materials like carbon-fibre-reinforced-polymers can improve the material’s specific performance characteristics, such as electrical conductivity, resistance to mechanical fatigue and crack propagation.

It can also improve structural damping, passive intermodulation reduction, electromagnetic compatibility shielding, re-machining and coating capabilities.

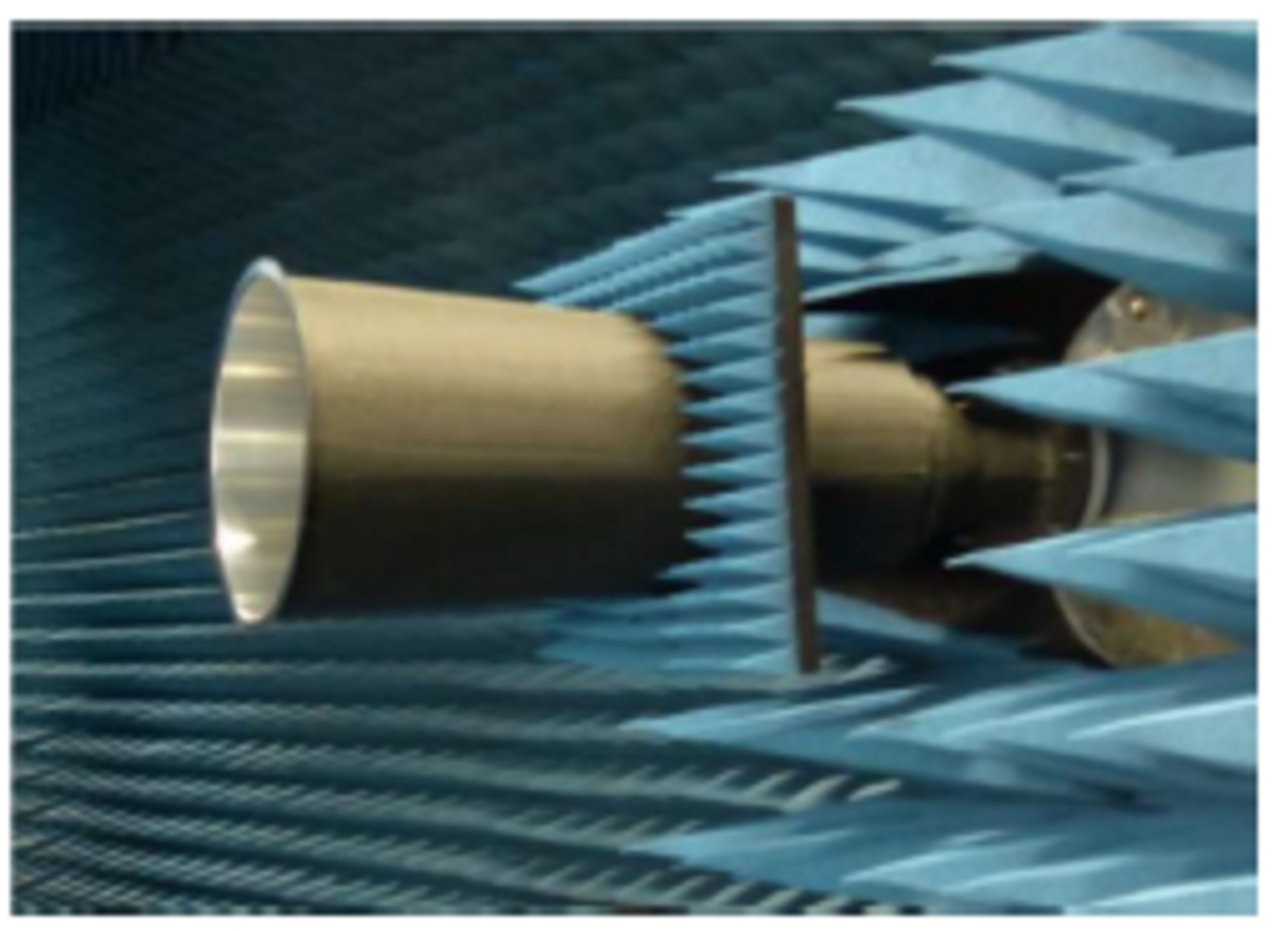

A GSTP activity with HPS in Germany aimed to select, develop and test space hardware to explore whether performance can be improved with carbon nano-materials-reinforced composites. Two demonstrators, an optical mirror and a feed horn, were built and characterised to demonstrate the benefit of the applied carbon nano-materials for the selected space applications.

For both demonstrators, a mass saving of around 50 per cent was achieved compared to a part made conventionally. For the feed horn, a radiofrequency test showed similar results to aluminium horns and the optical mirror showed promising thermal characteristics and reflectivity, despite cracks appeared during thermal cycling.

A carbon nanotube spray process was developed to TRL5 for the feed horn. The technology was used to allow grinding of the optical surface to a high accuracy before a metal coating was successfully applied.

The activity successfully demonstrated that carbon nanomaterial reinforcements have the potential to allow significant mass reduction in space hardware, while maintaining the functional performance of the subsystems onto which they are applied.

Next, the activity plans to develop the demonstrators up to TRL 8.

G617-182QT – the activity closed in 2019 but the final documentation was received in 2020.

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland