Large European Acoustic Facility (LEAF)

What is it for?

Anyone who has witnessed a rocket launch is struck by the amount of noise produced by it – even when standing several kilometres from the launch pad. Of course a satellite on top of its launcher is exposed to much higher levels of acoustic noise. Long before it gets to that stage its designers have to test that the satellite can withstand such a sustained sound.

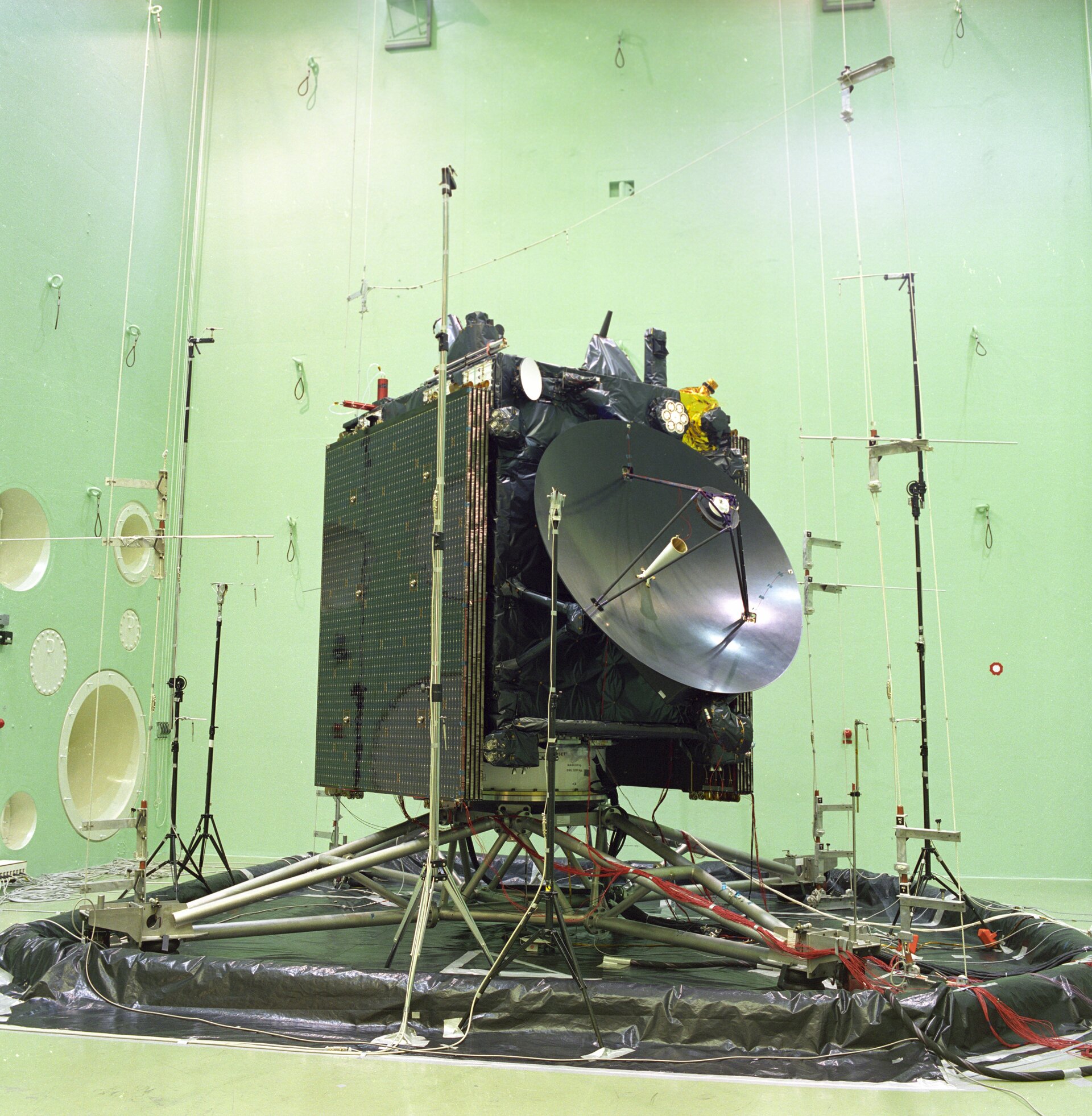

The largest European facility of its kind, ESA's Large European Acoustic Facility (LEAF) is a test chamber measuring 11 m wide by 9 m deep and 16.4 m high. Its walls are made of steel-reinforced concrete 0.5 m thick to contain the sound and are coated with a thick coating of epoxy resin to reduce noise absorption and increase internal reverberation.

One wall is fitted with noise horns of the same basic design as those seen in stereo speakers which can produce noise equivalent to multiple jet aircraft lifting off simultaneously from 30 metres away.

What kind of testing does it support?

The main objective is to reproduce realistic spectral noise pressure levels, comparable to those generated by the launcher engines and by the airflow passing along the fairing during atmospheric flight.

The LEAF provides the required environmental performance and offers adjustable noise levels and spectral shapes as well as test sequences and durations to meet different user requirements. The related infrastructure supports efficient test preparations, fast operations and flexibility – thanks to state-of-the-art instrumentation used for performance monitoring.

Continue reading below

What are its features?

The noise generation system consists of four different horns with low cut-off frequencies of respectively 25, 35, 80 and 160 hertz complemented by three high-frequency noise generators. A maximum overall noise level of up to 156 decibels can be achieved: provisions have been implemented to extend the level up to 158.5 decibels.

The facility has been designed especially to prevent noise break-outs, avoiding any disturbance to adjacent facilites. Furthermore, the acoustic chamber rests on springs to prevent propagation of vibration into the building structure. With a mass of 2000 tonnes the chamber is well suited for modal survey of large structures.

The instrumentation of the acoustic facility includes a microphone mounting system which allows an easy distribution of up to 32 microphones in appropriate locations around the test item. A large number of supervision points distributed throughout the chamber and standard moving trolleys offer considerable flexibility for spacecraft suspension.

The noise inside the acoustic chamber is automatically controlled and adjusted in real time by an acoustic control system using the average 1/3 octave spectrum of up to 32 microphones. This automatic control permits rapid spectrum adjustments, achieving the desired result in less than 30 seconds with a very tight tolerance (<± 0.5dB in the high power bands).

The LEAF is totally remote-controlled and safeguarded from a control room with the aid of a programmable logic controller. The facility is designed to ensure the safe operation of all subsystems and also protects the test article against excessive noise levels and test durations. The mechanical test data are sent to a dedicated mechanical and data handling computer that provides a detailed recording of parameter and test conditions, including test data acquisition and evaluation ensuring efficient online test analysis.

Since the acoustic noise in the LEAF is generated by gaseous nitrogen under pressure, the risk of test article contamination is excluded.

What benefits does it deliver?

European spacecraft of all shapes and sizes undergo acoustic testing in the LEAF facility, up to and including the double decker bus sized Automated Transfer Vehicle (ATV). Originally commissioned in 1990, the LEAF's performance has been improved over time, including troublesome lowest frequencies more likely to induce spacecraft vibration.

For more information

Please contact Gaetan Piret, ESTEC Test Centre Manager.

Gaetan.Piret @ esa.int