Ariane 6 – made in Italy

Italy, one of the ten founding Member States of the European Space Agency, is also home to ESA’s Centre for Earth observation (ESRIN), and naturally a strong contributor to Ariane 6, representing a share of 7.7 % of the development programme.

Avio is a company based in Colleferro, near Rome, Italy. Avio has been working on the Ariane family since the very beginning. Europropulsion was founded by Avio and ArianeGroup to ensure cooperation between France and Italy on the European Ariane and Vega launchers. It controls the development of solid rocket motors for ESA rockets.

This series of articles is looking at the parts and components needed to assemble the Ariane 6 rocket – supplied by companies from the 13 ESA Member States participating to the Ariane 6 programme. Together they contribute the best of their know-how to build Europe's heavy-lift launcher under the guidance of main contractor ArianeGroup who also designed the Ariane 6 rocket.

Europropulsion – providing the boost

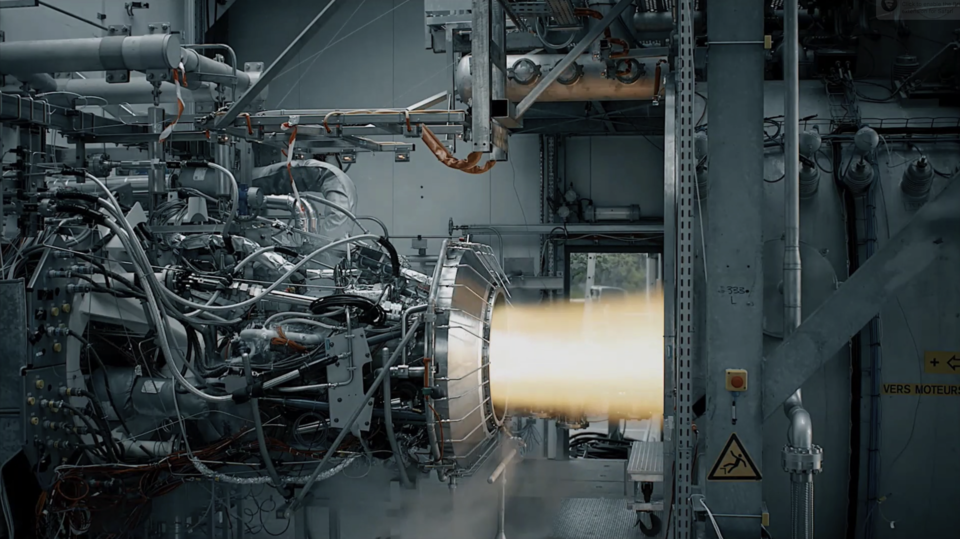

Europropulsion developed the P120C solid rocket motor, as well as its successor, P160C. Both will serve as the first stage of the Vega-C rocket and as the solid rocket booster of Ariane 6. The company is a joint venture between Avio and ArianeGroup.

Derived from the first stage of the Vega rocket, P80, P120C’s case is made of carbon-fibre, built from pre-impregnated epoxy sheets through filament winding and automatic fabric deposition in one segment at Avio’s Colleferro rocket factory near Rome, Italy.

The P160C qualification motor is one metre longer than the P120C. It was successfully tested on 24 April 2025 at the European Spaceport in French Guiana. The P160C is going to increase Ariane 6 and Vega-C performance, their payload capacity and competitiveness.

Each Ariane 6 comes with at least two boosters that each produce thrust equal to more than 35 jet engines. Without the boosters firing their immense thrust Ariane 6 would not even lift off the launch pad.

Regulus – mixing the solid propulsion

The explosive powder for the boosters is mixed by Regulus, majority owned by Avio since 2016. At a highly-controlled site at Europe’s Spaceport in French Guiana, Regulus mixes the rocket powder components into the specific quantities and shape for the P120C boosters.

Each booster holds up to 142 tonnes of solid propellant, which burns for about 135 seconds once ignited. The next generation boosters – the P160C hold – over 14 tonnes more solid fuel.

Once ignited the solid fuel Regulus prepares cannot be stopped, which is why strict safety regulations are in place. The Regulus site is far from offices and habitation, and when the loaded boosters are moved to the launch pad the area surrounding the trip along the road is evacuated. No mobile phones or other radio emitters that could trigger combustion are allowed.

Safran – rocket engine valves

In Turin, Italy, the former Microtecnica site now owned by Safran produces valves and pressure regulators for the Vinci and Vulcain engines that power the Ariane 6 upper and main stage. These valves have no easy task: they must regulate the pressure of cryogenic hydrogen, not only the smallest molecule in the Universe, but also at temperatures of –260°C, close to the coldest temperature in the Universe.

Founded in 1929, the site in Turin has been producing quality and precision mechanics for almost a century.

Avio – pumping propellants

Avio provides the liquid oxygen turbopumps for the Vinci and Vulcain 2.1 engines for Ariane 6.

Turbopumps pump the liquid propellants from the rocket tanks into the combustion chamber, where the propellants mix, react and increase in temperature. They do this by applying very high rotation speeds to the pump shaft, leading to the increase of propellant density. This way, propellants reach the engine combustion chamber at a high pressure in order to produce the amount of energy needed for the thrust, as they should.

Turbopumps deliver high power output in a small space, resulting in enormous power densities. They are exposed to extreme environments, such has temperatures ranging from below –180ºC to about 1000ºC, hold high-speed rotating blades, used to move the propellants, and aggressive compounds, in this case, liquid oxygen. Liquid oxygen is a strong oxidising agent that leads to violent reactions when in contact with plastics and reactive metals.

The Vinci oxygen turbopump has a lower flow rate and outlet pressure than the Vulcain 2.1. It comes with a new ‘Dynamic Seal Package’ which separates the hot hydrogen gas (600ºC) that drives the turbine from the cold liquid oxygen (-180ºC) that comes into the turbopump. The Dynamic Seal Package prevents hydrogen and oxygen to mix and, consequently, ignite, before they reach the combustion chamber. This seal withstands high pressures and temperatures, so its design has to be powerful!

ESA Member States decided to transfer responsibility for the liquid oxygen turbopumps from Avio to ArianeGroup France. This transfer is currently in progress.