EATOPS: turning satellite control rooms from space to Earth

The business of EATOPS is building space-style control rooms for terrestrial customers, and business is good. The French-Dutch-Norwegian company serves the oil and gas industry, applying techniques developed to control constellations of satellites to enable centralised oversight of multiple offshore platforms.

“Our space heritage gives us credibility with our customers,” explains EATOPS founder Alexandre Van Damme. “If we know how to handle one or more satellites, involving the continuous monitoring of hundreds of thousands of different variables, then we can handle oil rigs.”

The company was founded 15 years ago, with the support of ESA’s Technology Transfer Programme.

Alexandre explains that in this case the ‘transfer’ was a very literal one, bedding down space technology within a novel environment: “As a small-medium enterprise we were not credible in the offshore sector until we reached a certain level of expertise and experience. This meant discovering for ourselves what working on an oil rig was really like, flying there in helicopters and becoming knowledgeable in drilling techniques – it was quite a learning curve.”

But customers ended up receptive: “Our company really owes its origins to us looking at what space missions were doing with their control rooms, in particular to monitor constellations of satellites like GPS, Galileo and Earth-observing satellites such as the Copernicus Sentinels.

“The idea we had was that the oil and gas industry could really lean their production if they similarly installed centralised control rooms onshore for integrated operations instead of letting every oil platform operate individually, like an island.

“We were able to say that if you use our software tools you will improve your safety and work more efficiently, and this is exactly what has happened. This year has seen us multiply our turnover fivefold. Now we are in the process of enlarging the scope of our focus beyond oil and gas to, for example, power distribution, remote industrial operations and smart cities.”

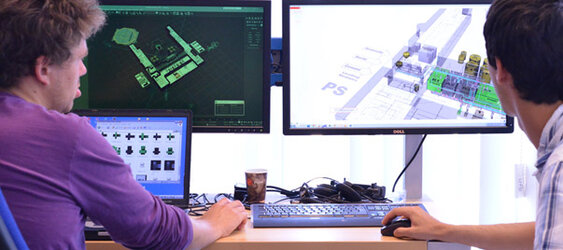

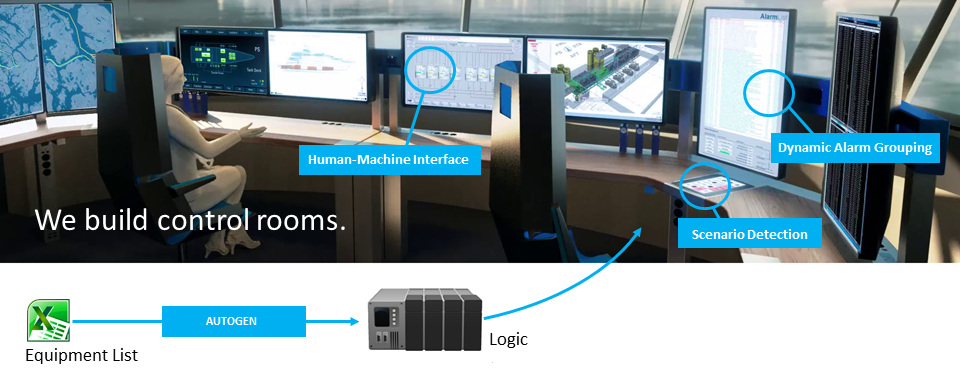

EATOPS control rooms are state-of-the-art, based around ergonomically optimised curved consoles and touch screens able to be rapidly reconfigured at the click of a switch, with voice loops to bring together specialist experts either in person or remotely.

But the physical control room itself is just the tip of the iceberg. The rest of EATOPS’s service involves designing software links between the control rooms and the myriad physical infrastructure they oversee. To achieve this, the company turned to another space industry innovation: autocoding – short for automatic code generation, employing software to write software.

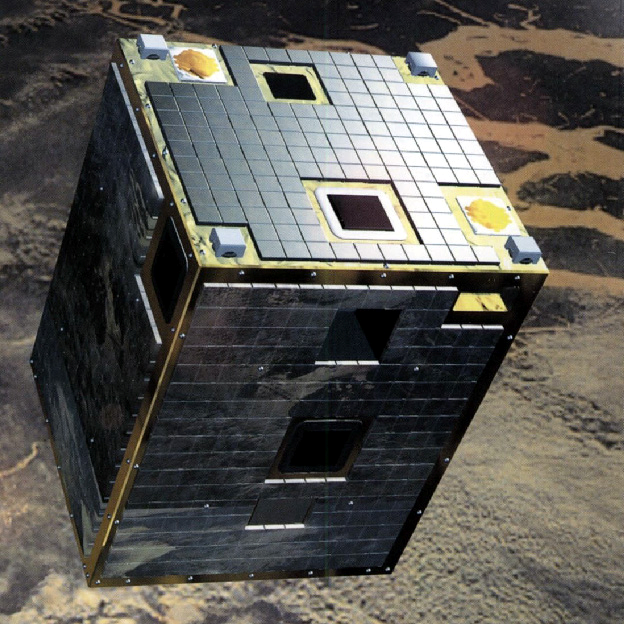

“ESA first made use of autocoding for our experimental Proba-1 Earth-observing satellite,” explains Joachim Fuchs, heading the Agency’s Software Systems Division. “It served as an efficient way of speeding up mission development to fit the available timeframe. The adopted solution was automatic code generation, allowing the use of modelling methods to generate better software by construction, ultimately accelerating the verification process also.”

The EATOPS team saw wider potential in the approach. In 2015 ESA’s Technology Transfer Programme financed a demonstration project to show how customers could benefit from what the company today terms its ‘Autogen’ service.

“Autocoding became a necessity for us,” says Alexandre. “Past generations of control systems had been set up on a manual basis in a very simple and linear way, which opens the door to many potential mistakes. It would be too expensive to plug in our products in the same manual way. We also needed our control software to be of a consistently high quality.

“We built a script with a simple level of abstraction, which works the same for one control system or many control systems. We tell our customers simply to fill in an Excel spreadsheet with all the valves, pumps, generators and other items that require oversight and Autogen reads it and executes all the logic behind it. It means we can perform what would otherwise be 10 000 hours of programming within a few hundred hours.

“And because we are using the same script for different systems, when a bug is identified and corrected, then the same correction is implemented across all control systems.

“It also makes it very easy to add new elements to any given control system, which will be important over the life of an oil rig, because oil reservoirs evolve in a dynamic way, with changing levels of pressure, water being injected to help liberate further oil, and so on. But instead of ongoing software tweaks, all our customers have to do is update their Excel spreadsheets and we do the rest.”

EATOPS remains based in Noordwijk, near ESA’s ESTEC technical centre and the ESA Business Incubation Centre that was its initial home. The company also does work for space customers.

As Alexandre concludes: “We maintain that link as it is part of our company’s foundation. It’s more than just friendship, but also good sense, because of all the new ideas that come out of the space sector, with potential to go further.”

ESA’s Technology Transfer Programme has opened a new Announcement of Opportunity and an Open Channel for companies to submit proposals for new Technology Transfer Proof of Concepts and Feasibility Studies, intended to demonstrate the relevance of a space technology/know-how for other technical fields as well as reduce the technical risk and confirm the market opportunity.

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland