Prehistoric cave pigment to shield ESA’s Solar Orbiter

A pigment once daubed onto prehistoric cave paintings is set to protect the ESA-NASA Solar Orbiter mission from the Sun’s close-up glare. Burnt bone charcoal will be applied to the spacecraft’s titanium heatshield using a novel technique.

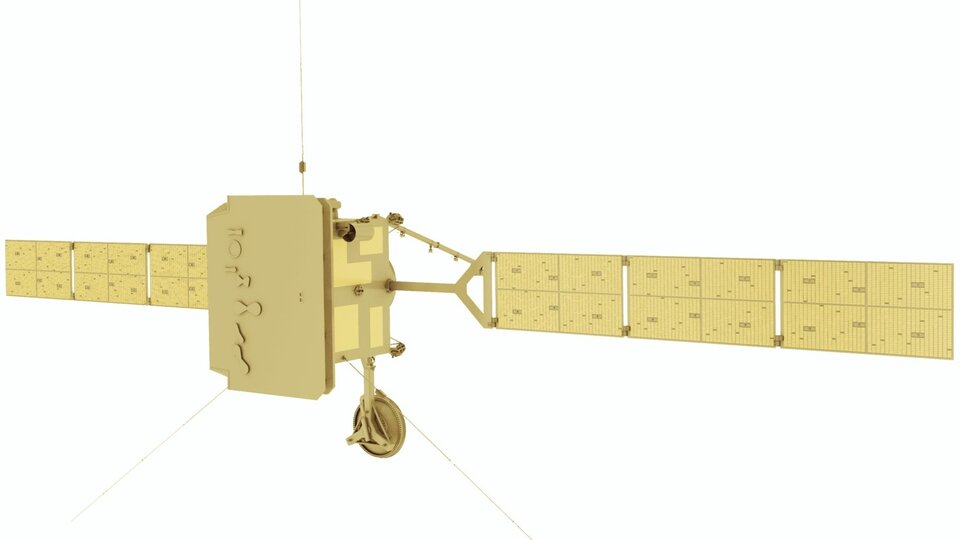

Solar Orbiter, due for launch in 2017, will carry a portfolio of instruments to perform high-resolution imaging of our parent star from as close as 42 million km – a little more than a quarter of the distance to Earth.

Operating in direct view of the Sun, the mission must endure 13 times the intensity of terrestrial sunlight and temperatures rising as high as 520°C.

“The main body of the spacecraft takes cover behind a multi-layered 3.1 m by 2.4 m heatshield,” explained Pierre Olivier, Solar Orbiter’s safety engineer.

“And Solar Orbiter’s instruments will operate at the far end of ‘feed-through’ lines that run through the shield, some under protective covers of beryllium or glass.”

Back in 2010, during the ‘Phase-A’ planning stage, ESA’s materials specialists began checking that the mission was indeed achievable with current manufacturing methods and materials.

“We soon identified a problem with the heatshield requirements,” said Andrew Norman, a materials technology specialist.

“To go on absorbing sunlight, then convert it into infrared to radiate back out to space, its surface material needs to maintain constant ‘thermo-optical properties’ – keep the same colour despite years of exposure to extreme ultraviolet radiation.

“At the same time, the shield cannot shed material or outgas vapour, because of the risk of contaminating Solar Orbiter’s highly sensitive instruments.

“And it has to avoid any build-up of static charge in the solar wind because that might threaten a disruptive or even destructive discharge.”

The initial choice – carbon-fibre fabric – was ruled out. Instead the team began looking for the answer outside the space business.

Medical solution

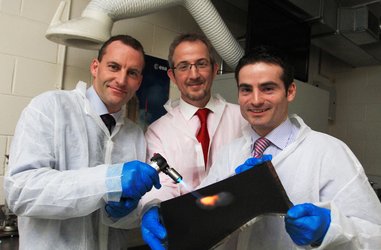

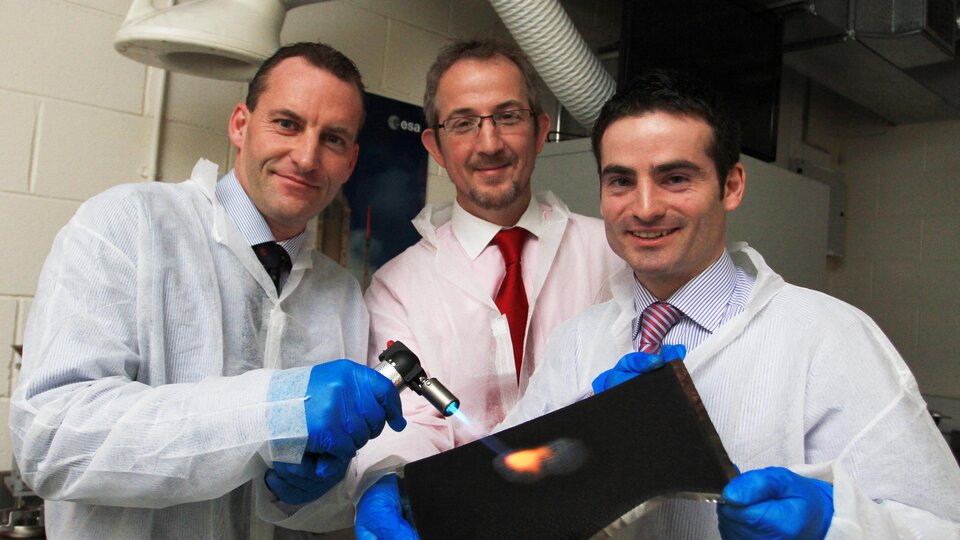

They found it in the shape of Irish company Enbio and its CoBlast technique, originally developed to coat titanium medical implants.

“The process works for reactive metals like titanium, aluminium and stainless steel, which possess a surface oxide layer,” commented John O’Donoghue, Managing Director of Enbio.

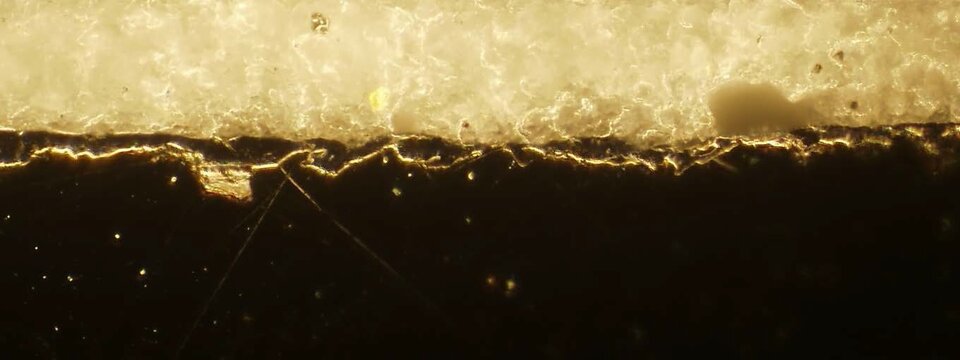

“We spray the metal surface with abrasive material to grit-blast this layer off, but – as the CoBlast name suggests – we also include a second ‘dopant’ material possessing whatever characteristics are needed. This simultaneously takes the place of the oxide layer being stripped out.

“The big advantage is that the new layer ends up bonded, rather than only painted or stuck on. It effectively becomes part of the metal – when you handle metal you never worry about its surface coming off in your hands.”

The material Enbio will apply to the outermost titanium sheet of Solar Orbiter’s multi-layered heatshield is called ‘Solar Black’ – a type of black calcium phosphate processed from burnt bone charcoal.

Prehistoric heritage

Burnt ‘char bone’ is widely used in everyday life, employed for everything from fertiliser and metal alloy production to purifying white sugar and filtering heavy metals out of water.

Its robustness is demonstrated by the endurance of prehistoric cave paintings over many thousands of years – burnt bone, along with wooden charcoal, serving as an early black pigment.

The CoBlasted Solar Black titanium has passed a gamut of testing in ESA’s Materials and Electrical Components Laboratories in the ESTEC technical centre in Noordwijk, the Netherlands – everything from accelerated lifetime exposure to sunlight and ultraviolet radiation to the deceptively simple-sounding ‘tape pull’ – applying then pulling off adhesive tape to see if anything comes with it.

Testing time

The treated titanium is now baselined for the heatshield, being developed by Thales Alenia Space in Italy. A prototype ‘structural and thermal model’ is due to be tested inside ESTEC’s Large Space Simulator, a giant vacuum chamber featuring a simulated Sun.

Another Enbio product, ‘Solar White’ is also being tested for other elements of Solar Orbiter exposed to the Sun, including its main antenna, instrument booms and solar array attachments.

“We’ve found that the Solar Black works well as a ‘tie layer’ foundation on metal, allowing us to place another layer on top – in this case a carefully tailored conductive white ceramic,” added Mr O’Donoghue.

“The rigorous ESA evaluation we’ve gone through has increased our knowledge and opened up new product possibilities, including a range of different tints.”

ESA is also studying wider uses for the coating process, including boosting the long-term surface robustness of telecom satellites, which typically operate for 15 years or more.

CoBlast and Enbio

CoBlast is a unique low-temperature and environmentally friendly process, chemical free and able to coat a range of different metal shapes to a thickness of a few thousandths of a millimetre.

Enbio is based at the University College Dublin campus in Ireland, allowing it to make use of the university’s test facilities, while ESA has also installed specialised equipment for dedicated space testing.

“It’s very much a symbiotic relationship, which has turned out well,” concluded Mr O’Donoghue. “Our work with Solar Orbiter has had a catalytic effect, opening doors for our company.”

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland