Developing smart, antistatic wires and cables

Space is a harsh environment and especially for polymers materials, which can be exposed to ionizing radiations (electrons, protons, photons), UV, atomic oxygen (ATOX), temperature cycling and other issues. These polymers are often used to make standard Space-approved wires and cables, but it leaves them susceptible to electrostatic discharges (ESD) under some circumstances and in some environments.

These ESDs are mainly due to the presence of excellent electrical insulation layers and the cable’s ability to store and build-up electrostatic charges due to the polymer’s intrinsic high resistivity.

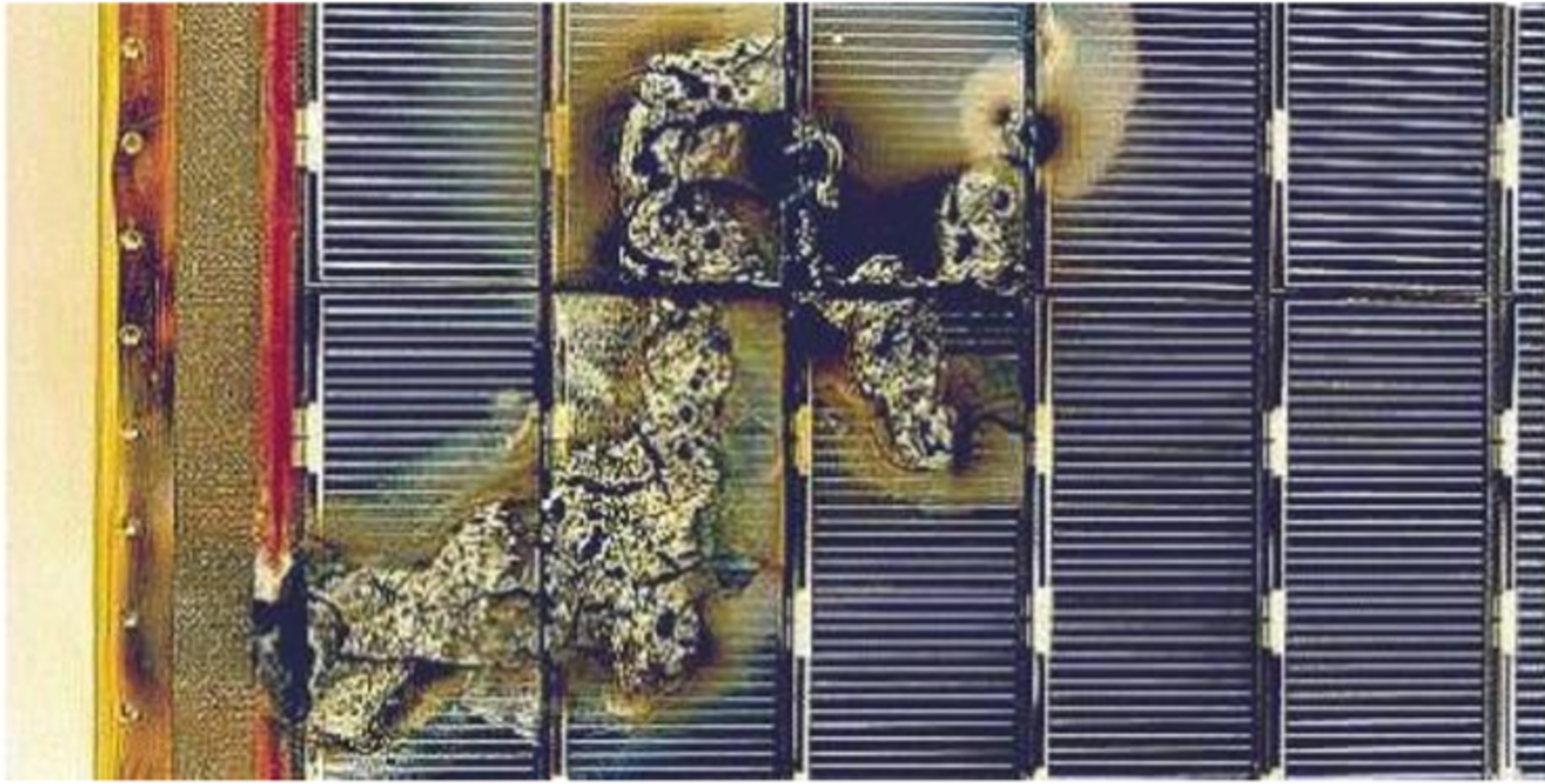

Incoming radiation charged particles can build-up inside dielectrics to break down threshold levels leading to arcs discharges into nearby sensitive circuits.

A standard way to protect wires and cables and others ESD sensitive components is to wrap them with conductive films, braid or coating in order to absorb and evacuate most of incoming charged particles toward the mass of the satellite. The main drawbacks of these solutions are the increase of products mass, volume, cost and reduced overhaul flexibility.

A TDE activity with Axon Cable (FR) has been exploring and developing various new and innovative products to replace these while still providing the best performance and optimised mass, to meet all Space requirements.

An innovative approach and explored solution to reduces the ESD risk for wires and cables without these drawbacks is to fully replace all highly insulative dielectric by materials that permit a fast enough evacuation of incoming charged particles to the nearest conductive layer. The main objective of this activity was to explore this concept by formulating, processing and testing new wire and cables materials insulation able to dissipate electrostatic charges that built up in space environment through the central metallic conductor of coated wires.

The main challenge was to formulate and process new materials with volume resistivities low enough to permit sufficient charge decay speed (for Space-ESD resistance), but at the same time maintaining a high electrical insulation performance of the finished wires (acceptable insulation resistance and dielectric strength).

It was possible to manufacture new antistatic materials and antistatic wire insulation ranging from 107 to 1014 ohm.cm. Three selected antistatic wires prototypes were extensively tested and compared and the results confirm the special antistatic behavior of all the three extensively tested wires prototypes, with additional acquired data, knowledge and know-how.

The activity hopes to lead to the first range of “Smart-antistatic ESDresistant” wires and cables solutions limited to very low voltage applications (≤250V) due to their special electrical behavior.

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland