Development of Flexible Cryogenic Insulation

| Programme: | TRP Workplan | Achieved TRL: | 4 |

| Reference: | T421-303MT | Closure: | 2016 |

| Contractor(s): | Active Aerogel (PT) | ||

With respect to the venting of the inter-stage compartments, there is the wish to avoid as much as possible use of helium purging (in general to be replaced by nitrogen). For articulating elements, such as flexible joints or compensators in feedlines, it forms a special challenge, since the rigid cryogenic foam insulation that is used for tanks and static line elements cannot be applied.

Objectives

The objective of this activity is firstly to assess the potential of available cryogenic insulations, or derivatives of existing products, to provide the required degree of insulation of flexible segments of stage lines with liquid hydrogen (LH2) in order to avoid use of helium flushing.

Achievements

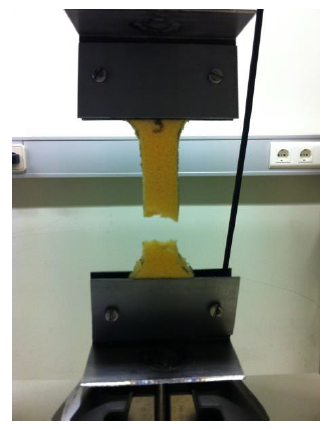

After initial tests on 4 different insulation materials (Level 1), including thermal conductivity, mechanical strength, cryo-pumping, etc., 3 insulation systems (combinations of materials) were selected for cryogenic articulation tests with liquid nitrogen (LN2) (Level 2). The best performing two combinations have been chosen to undergo final testing at 20 K (LH2 temperature) (Level 3).

Benefits

The benefit will be the possibility to avoid complex and expensive helium purging.

Further work

Application and testing of the selected insulation system on propellant feed-line.