Large Aperture Telescope Technology - LATT

| Programme: | TRP Workplan | Achieved TRL: | 5 |

| Reference: | T116-051MM | Closure: | 2015 |

| Contractors: | OHB-CGS (IT) (prime), ADS-International, Microgate, INAF-Arcetri, CNR-INO | ||

The use of large primary mirrors as entrance aperture of optical systems is crucial to get higher image resolution in next generation space missions. To be large, these mirrors must be conceived as lightweight and deployable, therefore actively controllable to compensate for thermo-mechanical deformations and optical quality. Besides, they must be safe during launch.

Large Aperture Telescope Technology (LATT) activity inherits experience on Adaptive Optics on ground based telescoped.

Objectives

The main objective is to develop, demonstrate and validate novel technologies for lightweight large aperture deployable telescopes. This was achieved by building appropriate breadboards (BBs) and testing their performance:

- Optical BB: for verification of Lightweight Mirror Technologies & Safe Launch locking device

- Deployment BB: for verification of the Deployable mechanisms

Achievements and status

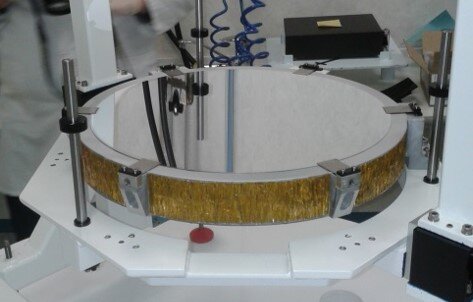

The core of the LATT approach is a 1-mm thick Zerodur glass shell with 5-m radius of curvature as the optical surface, actively shaped by contactless fail-safe voice-coil actuators, controlled in close loop by an internal metrology fed by capacitive position sensors along their stroke (+/-500μm).

The mechanical support is an ultra-low mass CFRP + Aluminum honeycomb structure, housing the actuators and the electronics and providing the electrostatic locking capability for the shell during launch.

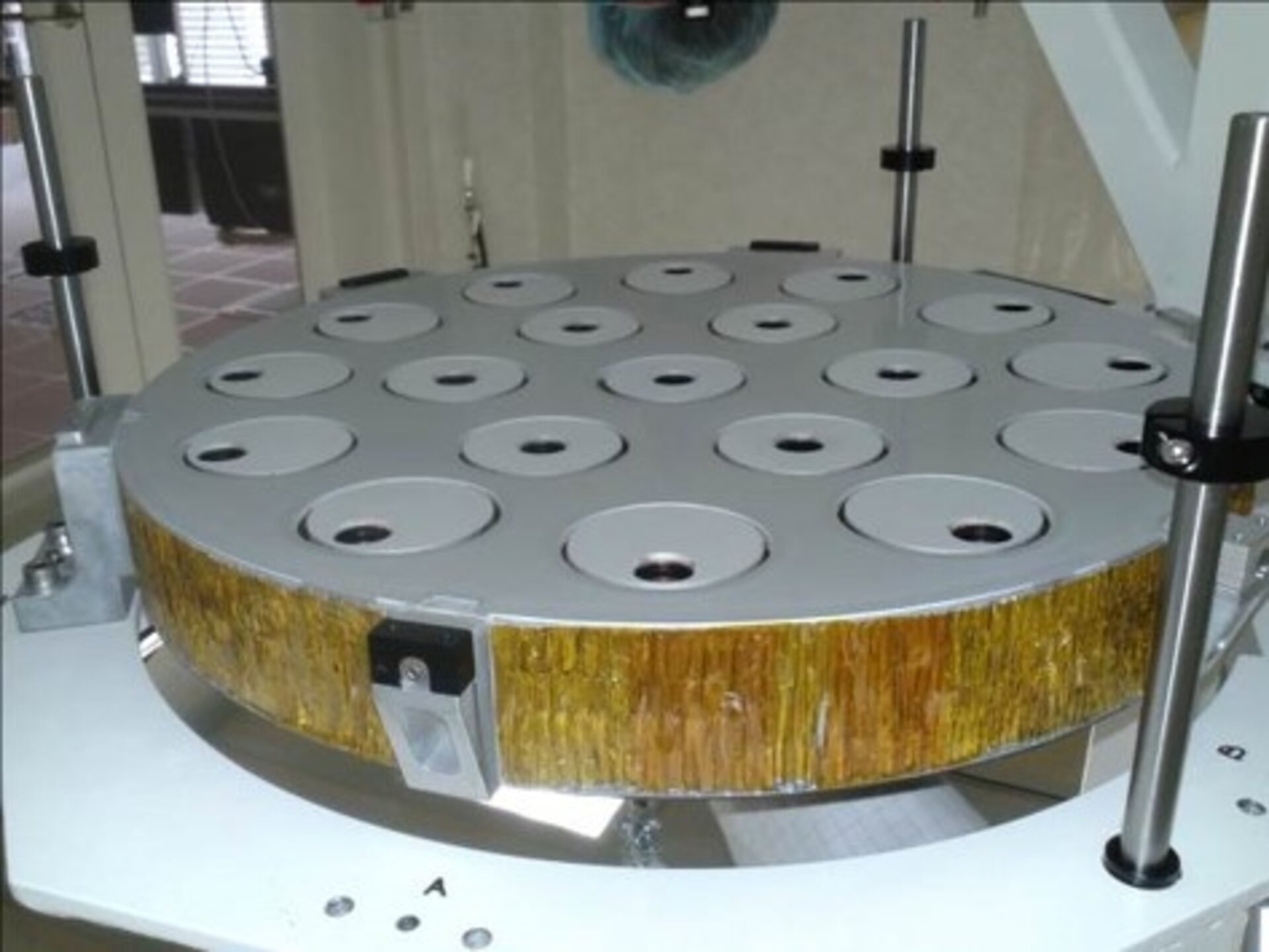

A 40-cm diameter, spherical F/6 demonstration prototype with 19 actuators was assembled (i.e. the Optical BB); its areal density is around 17 kg/m2 and the power dissipation is ~55 mW/actuator. It was subjected to a qualification campaign, including optical, thermo-vacuum, thermal cycling and vibration tests.

Benefits

Lightweight active mirror breadboard successfully passed the planned environmental tests. The technology is already suitable for primary active mirrors, with some improvements on some subsystems.

Next steps

A GSTP activity is proposed to optimize some elements, to reduce the areal density, to increase the TRL and possibly to prove the concept with more than one petal.

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland