Turntables used to make uniform spectral filters

The uses and manufacturing of spectral filters is under continuous evolution.

More complex filter designs result in better performance but can also introduce side effects, such as increased wavefront errors and higher sensitivities to the angle of incidence. Non-uniformities and bumps and errors in the surface coating can cause the reflected or transmitted light to create wavefront errors, especially on thick dielectric coatings on flat components.

A recently closed TDE activity with Fraunhofer IST and the Laser Laboratory Goettingen, both in Germany, aimed to develop spectral filters with high transmission and reflection and low wavefront aberrations. Although uniformity was considered, the main issue with the beam splitter was to demonstrate the ability to fabricate highly uniform coatings on relatively large area.

Despite this, the activity was able to successfully design and manufacture a spectral bandpass filter with a low wavefront error, as intended, by using a dichroic beam splitter and a spectral band pass filter on a curved substrate.

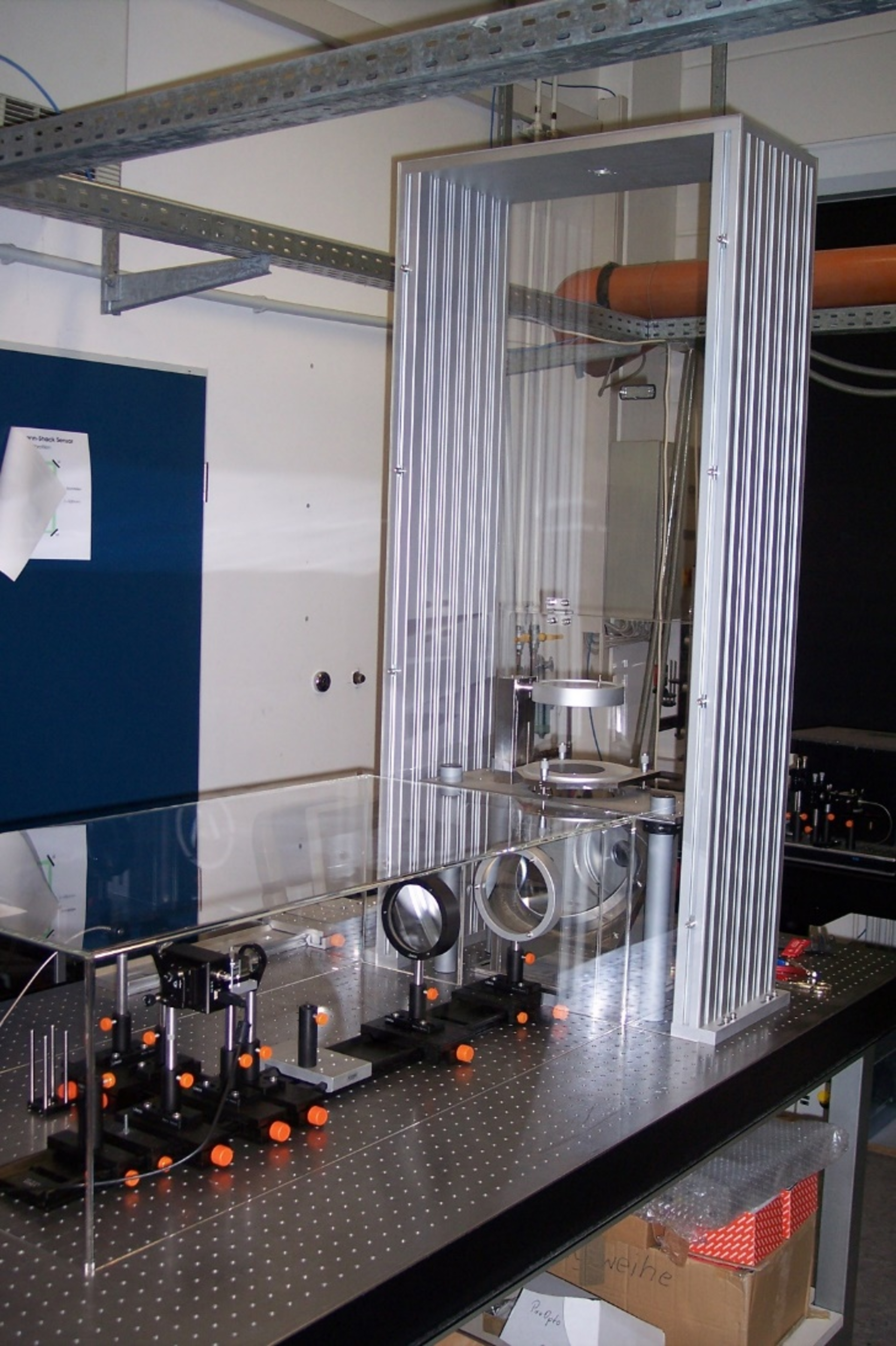

Unlike previous attempts to develop such filters, this activity controlled the spatial thickness distribution by using a higher thickness of the coating stacked at the edges. This thickness control was found to be necessary to ensure the spectral filter profile across the curved substrate. TO create the uniformity across the lens, a setup was built to hold and rotate lenses on a fast-rotating turntable.

The activity found that manufacturing the filters with very high uniformity (>99.85%) required a more sophisticated set up but the activity was able to improve coating design, which will allow for the removal of dedicated filter substrates in future instrument designs.

Both components (the beam splitter and bandpass coating) were successfully tested to see if there were any changes in the spectral properties before and after environmental tests, including humidity, thermal vacuum cycling and abrasion.

T116-403MM closed in March 2020

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland