Alternative polishing layers on ceramic materials for high performance optical mirrors

| Programme: | TRP Workplan | Achieved TRL: | 4 |

| Reference: | T116-309MM | Closure: | 2015 |

| Contractor: | Reosc (FR) | ||

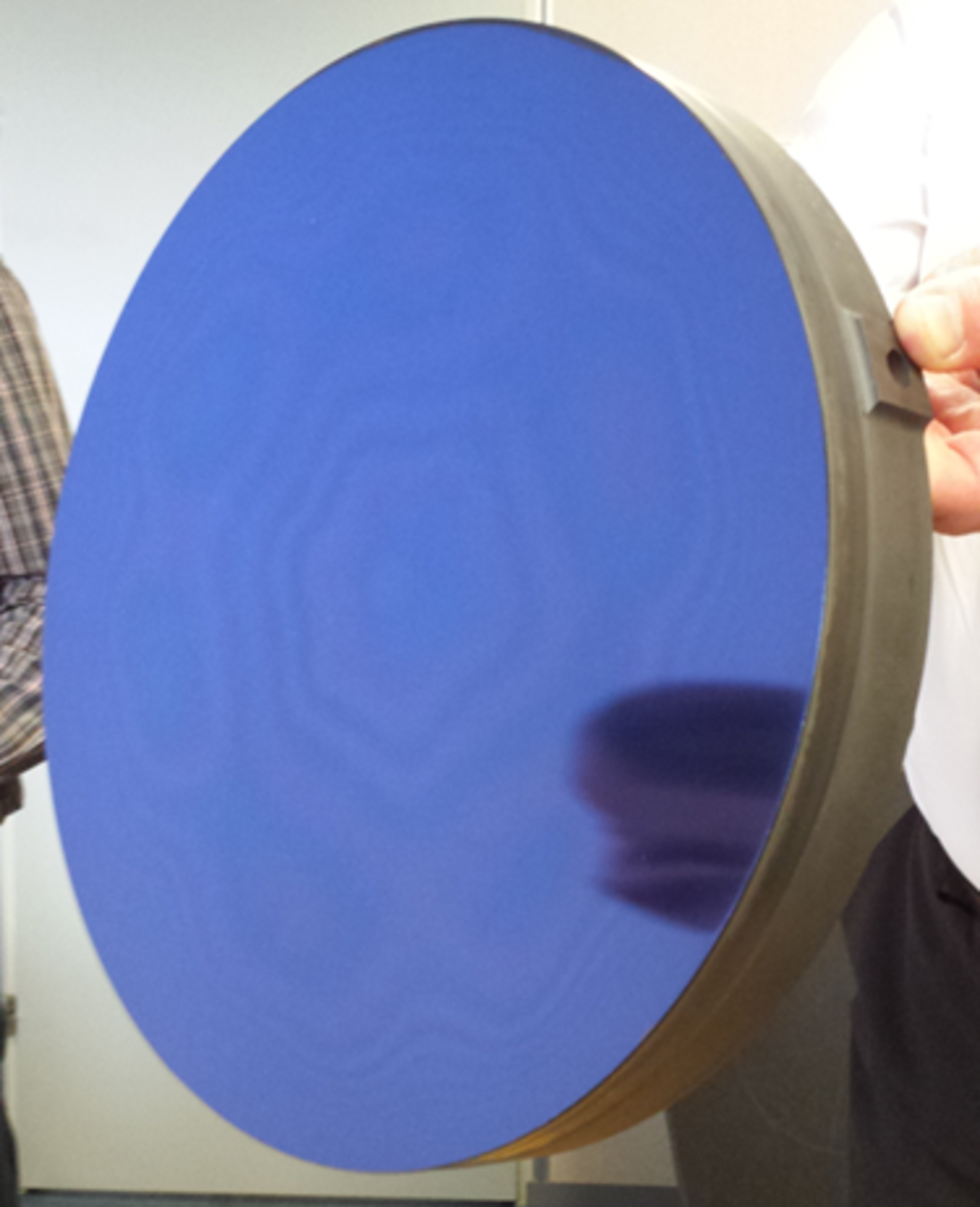

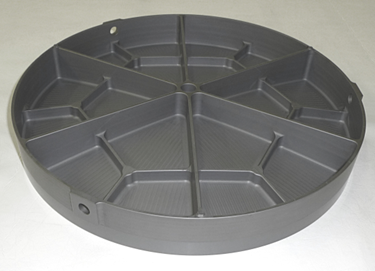

Telescope mirrors for the visible spectrum made of ceramic material substrates require a polishing layer due to the ceramic material intrinsic minimum achievable surface micro-roughness caused by point defects/material micro-structure. For such applications the ceramic bulk mirror needs a polishing layer to achieve a very low surface micro-roughness. Typically, a Chemical Vapour Deposited SiC polishing layer is applied that involves a risky and not accurately predictable process.

Objectives

The objective of this activity is to investigate alternative polishing layers on the two major European ceramic materials for high performance optical mirrors. The activity is aiming at a reduction of the polishing time, improvement of the surface micro roughness while maintaining a very good wave front error performance.

Achievements

An alternative layer has been successfully developed. Polishing quality (wavefront error, surface roughness) has been confirmed to be better than existing layers. Mechanical stability and performance at low temperatures is demonstrated by test.

Benefits

Developed polishing layer allows for lower surface roughness and easier polishing.

Further work

A follow-on activity with the objective to apply the developed polishing layer to a larger mirror is not longer foreseen, as CNES has launched an activity with a quite similar approach.

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland