Compliant Mechanism Based on Additive Manufacturing - Activity 1

Compliant mechanisms are well known in space applications under different configurations and categories, from flexure joints and pivots to special spring elements or actuation devices. Normally, they are employed where friction-free motion is needed, to ensure high precision and position accuracy, such as in the tilting and tipping of mirrors or thrusters. The design of these mechanisms is notoriously challenging. Compliant mechanisms with complex architecture are generally composed of various precise parts that need to be machined, verified, aligned and fixed together.

Additive manufacturing can allow a freedom in geometry that could mean new designs and extended capabilities for these mechanisms. In particular, the drastic reduction of the assembly process and the possibility to build more complex 3D compliant structures. The absence of friction and wear allows the device to be lubrication-free, extending its life and improving cleanliness while reducing sources of unpredictable errors.

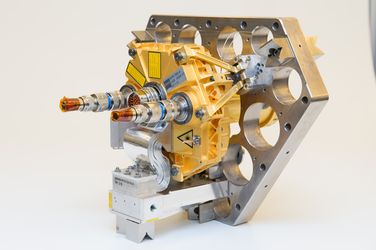

A GSTP funded activity “COMAM” started in 2018, here CSEM (Switzerland) took advantage of its 30 years expertise in compliant mechanisms for space to design the Compliant Rotation Reduction Mechanism (CRRM). The CRRM allows for rotary motion reduction with a factor of 10, a useful function for scanning, pointing, calibration or flip mirror mechanisms. The Additive Manufacturing of the mechanism was performed by a local company 3D Precision, while the performance tests were performed by Almatech SA.

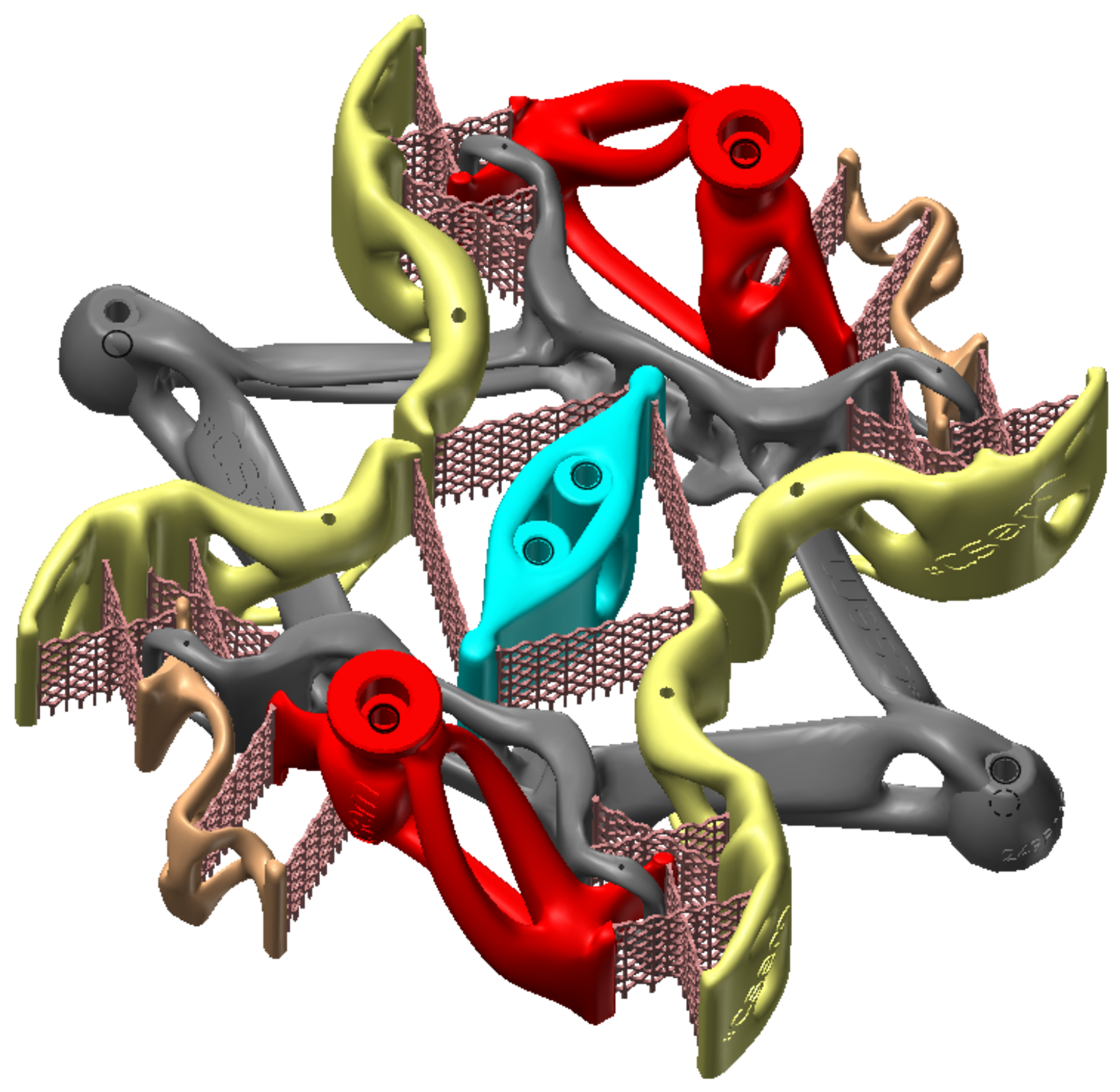

The activity demonstrated the major advantages of additive manufacturing, such as the design freedom and the possibility to build monolithic complex shapes. This design – integrating 24 flexure blades among which 16 are interlocked (patent pending) to form crossed pivots and 8 intermediate stages – would not be possible in such a small volume without the use of additive manufacturing. Moreover, no alignment is needed between the flexure structures to ensure a proper cinematic. Thanks to a thorough combination of parametric and topology optimizations, the mass and eigen-frequencies were significantly improved and provided a first eigen-mode higher than 550 Hz.

Although very encouraging, the performance and lifetime test results suffer from the distortion of the two breadboard models manufactured and tested. Further information about the CRRM development – including test results – is available in the CEAS Space Journal. A video of the CRRM is also available.

To maintain its position of key player in the field of compliant mechanisms, CSEM invested significant resources in parallel to the COMAM project to mature its know-how in design, production and testing of compliant mechanisms based on additive manufacturing. The experience thus accumulated has been recognized by ESA which once again selected CSEM to develop a new mechanism based on additive manufacturing: the CRTM (Compliant Roto-Translation Mechanism). This new TDE project ANGELE started in January 2022!

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland