Green alternative found for polyurethane as a launcher material

A recently completed TDE activity has found an environmentally friendly way of manufacturing polyurethane so it can be used in space.

Polyurethanes (PUs) are versatile materials widely used also for space applications due to their stability under challenging environmental conditions. However, traditional manufacturing processes use toxic chemicals called isocyanates, can be dangerous to the health of those working with them and are unsustainable. This activity wanted to find out if it was possible to manufacture a green alternative that could still withstand extreme conditions.

Pus are particularly useful in launcher applications as thermal insulation foam material, conformal coating and potting, so the activity focused on these three applications.

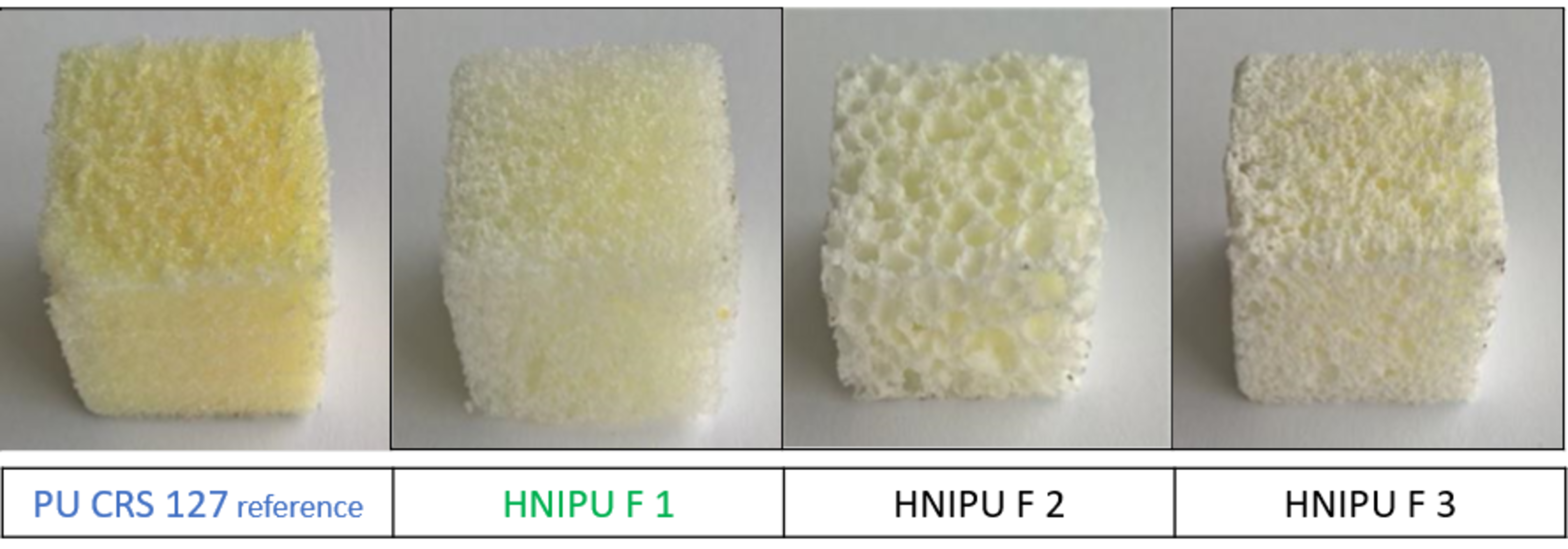

The activity, conducted by TOSEDA s.r.o. in the Czech Republic, designed a rigid polyurethane foam for insulation of tanks for liquid propellants of launchers, a flexible two component polyurethane conformal coating and a rigid epoxy potting system. The developed systems replaced 100% of the toxic isocyanate hardeners and up to 60% of the materials used with renewable versions.

The novel (in Europe) conformal coating and potting system were not as compliant with the key parameters space-qualified materials need as hoped, especially in terms of their tensile strength and pot life. But, with small adjustments, it can be predicted that the novel (H) NIPU conformal coating and potting systems can replace the traditional polyurethane materials in selected applications.

While the developed rigid foam did not fulfill the majority of the key parameters defined for it to be a suitable replacement as external thermal protection of tanks for liquid propellants, it showed high potential to be implemented as external thermal insulation on existing and future launch vehicles by spraying, without the use of hazardous blowing agents.

Overall, the activity confirmed that these novel polyurethane materials can indeed be formulated in an environmentally friendly way and manufactured using more green and sustainable techniques.

The TDE activity 4000119685/ T724-502QT closed in July 2019.

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland