Metal Matrix Composites (MMCs) as high performance metallic material

| Programme: | TRP Workplan | Achieved TRL: | 2 |

| Reference: | T724-303QT | Closure: | 2016 |

| Contractor(s): | AAC (AT), Tecnalia (ES), RHP (AT), RTBV (AT), TU Wien (AT) | ||

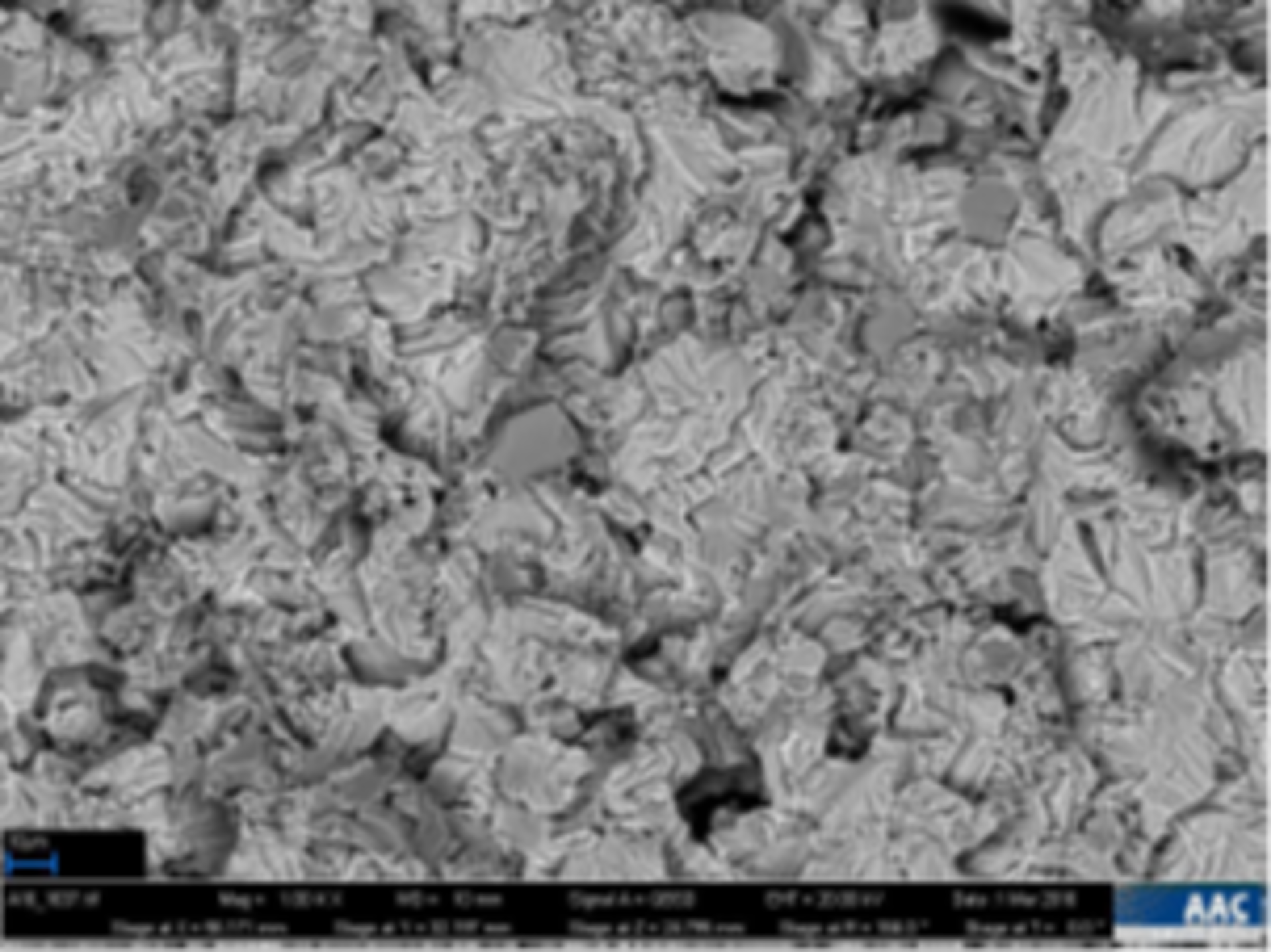

Metal matrix composites (MMCs) have developed during the last decade and some of them could be used for structural applications – potentially boosting the performances by 50% or more compared with pristine metallic solutions. Developing MMCs is challenging as it requires excursions at high temperature where undesirable chemistry / stresses generation can be initiated.

Objectives

The main objective of the study was to investigate few materials showing, on paper, good performances. Mg-8%Li reinforced with carbon fibres, Ti6Al4V reinforced with TiB and Mg (AZ91) reinforced with alumina nano particles.

Achievements

In Mg-Li matrix composite, Li diffuses very quickly in the carbon fibres inducing swelling and Lithium carbide formation – more work would be needed to have reinforcement compatible with Li, this later providing very interesting properties to Mg when added in large enough quantity (8%). In Mg reinforced with nanoparticles, particle distribution remains unsatisfactory, the mixing proved challenging. As back up, micro-size particles were used and processing developed. In Ti6Al4V, TiB has been swapped for TiC with lower vol%. The composites passed the SCC test opening the door to structural applications.

Benefits

The Ti64V based composite is a candidate for high performance applications. Activity conducted with unofficial sub-contractor: Slovak academy of Science which worked on Mg-Li matrix composite - allowing this institute to understand the space industry requirements.

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland