Unveiling technologies for future launch vehicles

ESA safeguards Europe’s guaranteed access to space through its Future Launchers Preparatory Programme, FLPP.

FLPP weighs up the opportunities and risks of different launch vehicle concepts and associated technologies.

Its demonstrators and studies hone emerging technologies to give Europe's rocket builders a valuable head-start as they begin the demanding work of turning the chosen design into reality.

From lab to launch

Based on a standardised scale of “Technology Readiness Levels” or TRL, technologies that have been demonstrated in a laboratory environment at Level 3, are further developed within FLPP and tested via integrated demonstrators to raise them to TRL 6.

Once a technology has reached level 6, much of the risk linked to using a new technology in a space environment has been mitigated. It can be quickly transferred to a development up to flight (TRL 9) with optimised cost and schedule.

FLPP activities

FLPP defines the concepts and requirements for new space transportation systems and services. Technologies are selected on their potential to reduce cost, improve performance, improve reliability, or on their ability to fulfil the specific needs of an identified system, demonstrator or mission.

Within the programme, integrated demonstrators are built by combining multiple technologies into one system or subsystem so that industry can use the technology with confidence.

Access the video

Flagship projects

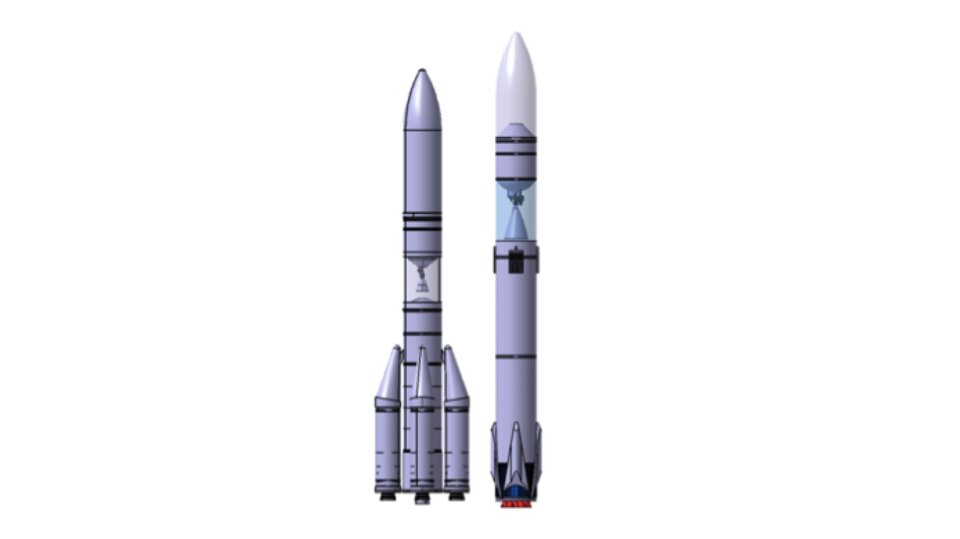

Future space transportation services and systems are assessed on their competitiveness and economic viability.

ESA’s objective is to develop a robust and flexible Space Transportation ecosystem which serves European needs. To achieve this, ESA brings together its various programmes and business units, Europe's launch service provider, and industry such as spacecraft manufacturers and innovative start-ups.

FLPP projects cover fields such as propulsion, materials, reusability, production methods and avionics.

Propulsion: Prometheus, a precursor of a reusable 100-tonne class rocket engine aims to slash costs through an extreme design-to-cost approach, new propellant and innovative manufacturing technologies.

Additive layer-by-layer manufacturing of engine parts enables faster production, with fewer parts. Liquid oxygen–methane propellants are highly efficient and widely available and therefore a good candidate for a reusable engine. A full-scale demonstrator will be ready to test on ground in 2020.

The Expander-cycle Technology Integrated Demonstrator, or ETID, paves the way for the next generation of cryogenic upper stage engines in Europe in the 10-tonne class.

Testing of a full-scale ETID demonstrator was recently completed proving the latest propulsion technologies. The test results are now undergoing full analysis including cross-check to improve numerical models as well as the full inspection of the tested hardware.

Synergy between the Prometheus and ETID projects has yielded game-changing additive manufacturing techniques for combustion chambers that reduce cost and lead time.

A 3D-printed small-scale combustion chamber design for upper stages was tested at DLR Lampholdshausen. It uses ‘storable propellants’, called such because they can be stored as liquids at room temperature. Rocket engines that are powered this way are easy to ignite reliably and repeatedly on missions lasting many months.

Continuing on from this project and considering the environmental impact of the currently used storable propellants, investigations are ongoing to prepare tests with identified new environmentally friendly propellant combinations that remain storable but are much less toxic.

Further hybrid propulsion studies have been initiated following the launch of the Nucleus sounding rocket in Norway last year, which successfully reached space by attaining a final altitude of over 100km. Watch the full videos here.

Materials and processes: FLPP has been investigating alternative materials to make rockets lighter. Carbon composite is being used to replace aluminium for lighter upper stage structures and fuel tanks, as well as for rocket fairings that protect the payloads on their way to space.

Closed-cell polyurethane foam material is being sprayed on as external tank insulation for cryogenic upper stages and a new solution for tank bulkheads is currently being developed.

Secondary launcher structures could benefit from additive layer manufacturing for fracture critical structural parts built in titanium, high strength aluminium alloy and polymer.

Reusability: FLPP is also working on launch vehicle reusability - a successful drop test recently proved some of the technologies for a reusable first stage of a microlauncher.

Wind tunnel testing and computational fluid dynamics are providing insights into European capabilities to control the descent of a launcher’s first stage, back to the ground.

In addition, an ongoing project featuring a ‘flying testbed platform’ capable of carrying payloads will soon start performing short take-off and landing test flights.

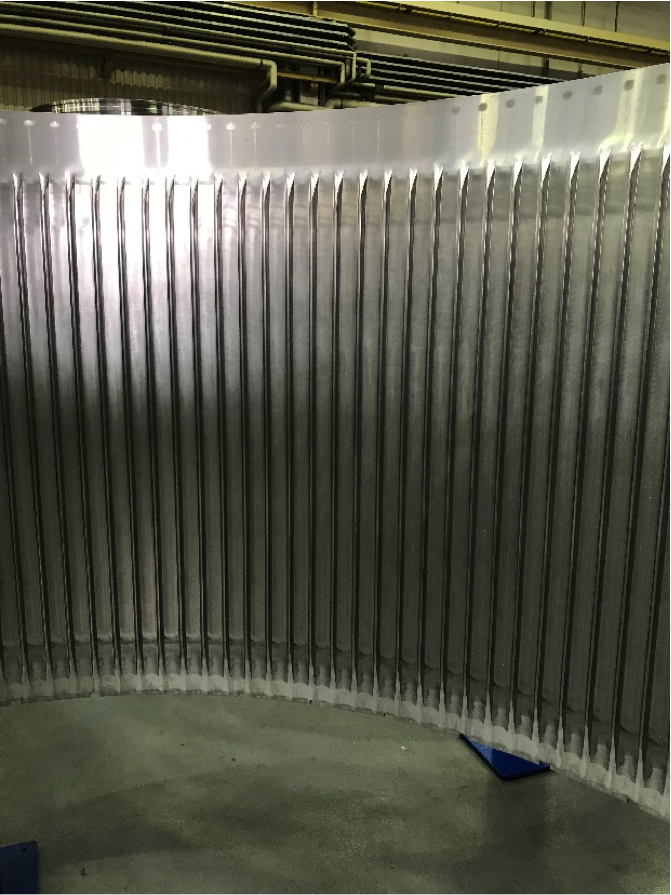

Structures and mechanisms: Various new production methods are improving manufacturing efficiency, for instance, a ‘Flow forming’ technique shapes a metal element in a single step. This has been demonstrated in recent manufacturing trials co-funded between ESA and NASA Langley.

This technique reduces weld seams making rocket structures stronger and lighter while speeding up production. It is also better for the environment because it saves energy and there is no waste material. A 3 m diameter aluminium demonstration cylinder that would be used as an interstage was successfully manufactured and tested recently.

FLPP is investigating electro-mechanical actuators for smoother separation and jettisoning of launcher payloads that would also slash costs for future evolutions of European launchers.

Avionics: Technologies in this domain evolve rapidly. Focus is given on increasing automation to reduce the level of Guidance Navigation Control (GNC) effort required during a mission and to provide responsive launch capability. FLPP is currently investigating On-Board Real-Time Trajectory Guidance Optimisation technology for future reusable launchers.

A new low-cost avionic system heavily benefiting from COTS components and rapid and effective GNC design, verification and validation will be demonstrated with a sounding rocket launch later this year. This will also serve as a useful testing platform to address new technologies in the launcher domain.

Future wireless communication will reduce the need for wiring on launch vehicle structures and increase flexibility.

Rockets are the backbone of all space-based endeavours. ESA in partnership with industry is developing next-generation space transportation vehicles, Ariane 6, Vega-C, and Space Rider. At Space19+, ESA will propose further enhancements to these programmes and introduce new ideas to help Europe work together to build a robust space transportation economy. Join the conversation online this week by following the hashtag #RocketWeek

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland