Improving the Gas Loop Heat Switch

Gas Loop Heat Switches have several issues, such as high thermal losses. As such, multiple iterations have been suggested over the past decade. These have improved several areas, from increasing cooler-application distance (up to 1-2m), reducing mass budget per length and lowering micro vibration transmission levels.

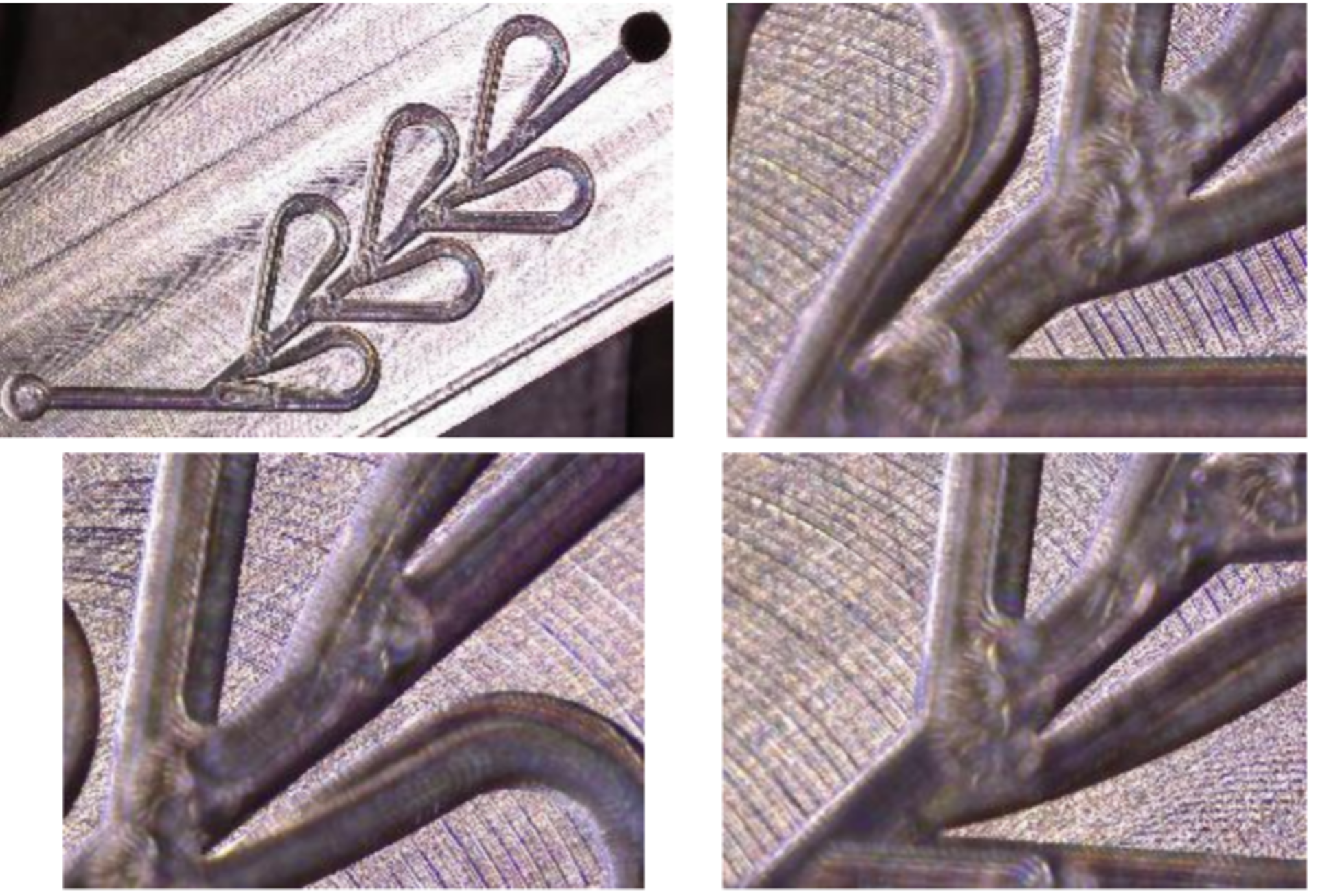

Now, as part of a TDE activity with Air Liquide Advanced Technologies in France, one of these concepts has been taken forward to be manufactured and tested.

This version of the gas loop heat switch uses a fraction of the mass flow as other gas loops. Here, the cold head heat exchanger sub-cools the by-passed gas and the heat exchanger is placed on the focal plan to allow the detector to cool.

To optimise the technology the new design has decreased the parasitic heat losses and reduced the overall mass, while increasing the component’s ability to integrate with systems.

The activity was able to successfully develop a simplified Gas Loop Heat Switch with high conductivity of 350mW/K. But the cooling performances are highly impacted by the integration of the switch, and the cooling power delivered to the application exchanger was reduced to 2.2W at 80K instead of the intended 6W at 80K.

As the origin of performance losses have been estimated, now design modifications have to be applied on the breadboard to confirm the expected performance gain experimentally.

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland