Constructing, recycling and refurbishing satellites in space

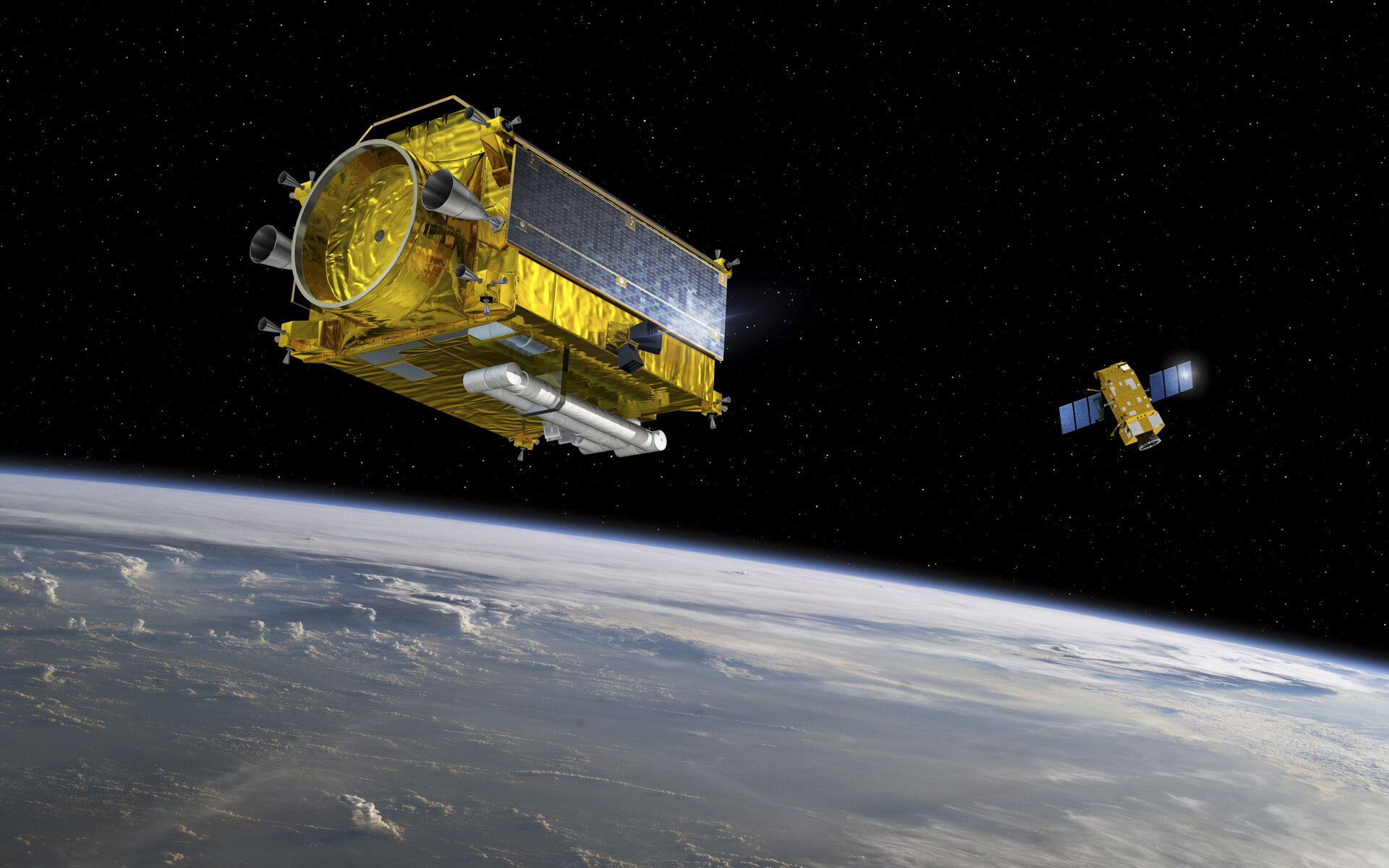

Better quality, longer-lasting spacecraft AND a more sustainable space environment? This vision is in reach thanks to efforts by ESA’s Discovery & Preparation elements to advance our ability to manufacture, assemble, recycle and refurbish satellites in space.

Construction in space

Many spacecraft are equipped with large structures – think antennas, booms and solar panels, for example. These are often stowed for launch and deployed in space. As our demands for satellites with higher performance and better capabilities grow, so does the size and the mass of the structures mentioned, and the complexity of their deployment mechanisms.

What if we could instead build them in space? One possibility is to take up raw material and 3D print parts. Alternatively we could consider sending up individual parts and putting them together much like a LEGO kit; the International Space Station was built like this with the help of astronauts, but satellites would get no such onsite human support.

Manufacturing or assembling satellites in space would make launches more efficient, we could design lighter satellites, and initial investment cost would be lower, because we could adapt or even rebuild satellites throughout their lifetimes.

But it comes with challenges. Who is responsible if something goes wrong? How do we control the quality of structures built in space? How do we 3D print in a vacuum? And – knowing how unreliable printers can be – what if the printer breaks down?

Servicing and refurbishing in space

A goal more achievable in the short term is refurbishing or refuelling satellites whilst they are still in orbit around Earth.

This could extend the lifetimes of satellites that just need a little extra fuel or a replacement part, quickly use an existing satellite for a new purpose, reduce the copious time and money that comes with building and launching new satellites, and reduce the amount of space debris produced from defunct satellites.

On the longer term, it could be possible to entirely separate satellite platforms and their payloads. When a platform is exhausted, the payload could be moved to a new platform, considerably extending its working life. Likewise, new payloads could be exchanged on a given platform. And individual parts like antennas and solar panels could even be leased between satellites.

What is Discovery & Preparation doing in this area?

A satellite that is manufactured, assembled or even refurbished in space must be designed in a completely different way to one built on Earth.

To kick start this forward thinking, in 2019 the Discovery element of ESA’s Basic Activities set up the OMAR (On-orbit Manufacture, Assembly & Recycle) initiative with three questions in mind:

- What are the most useful applications of in-orbit manufacturing, assembly and recycling?

- What technologies already exist to make it possible?

- What new technologies need to be developed?

OMAR is a two-step process:

- 2019: A small, preparatory Concurrent Design Facility study at ESA, bringing together experts from various fields to get a clearer view on the types of mission that could benefit from in-orbit manufacturing and assembly, and a better understanding of the implications on a spacecraft’s design.

- 2019–2021: Four studies funded by ESA Discovery and carried out by industry addressing the applications and technology development requirements in more depth. These studies are described in the section ‘OMAR studies’ below.

OMAR studies

In one study, European technology corporation OHB explored in-orbit manufacturing and assembly for three space mission cases.

The first case was a telecommunications satellite 3D printed in low-Earth orbit; OHB found that our current printing techniques would be very slow, and a more competitive option could be to build launch kits on Earth that could be assembled in orbit.

The second case consisted of Earth observation satellites in low-Earth orbit. OHB explored whether individual satellites could be upgraded or repurposed using one in-orbit refurbishment station; they found that even with existing technology, we could build such a station that could quickly change speed and direction to whizz between satellites.

The third case involved constellations of navigation satellites in medium-Earth orbit. The lifetime of a navigation satellite is limited by the lifetime of its onboard atomic clock and fuel supply; using three in-orbit refurbishment stations to replace the clocks and refuel the satellites, OHB found that it would be possible to reduce expensive deorbiting of old satellites and launching of new ones.

They found that 95% of a spacecraft could potentially be assembled in orbit, whilst less than 30% could be manufactured in orbit.

The study concluded that in-orbit recycling is still a true challenge; it would be technically extremely complicated, and it is still not clear if the resources used to capture and process the waste in space would be larger than those saved by recycling.

For this reason, Thales Alenia Space proposed to start with in-orbit refurbishment – it would bring immediate benefits and current technology developments are on their way to enabling it. Refurbishing satellites, including replacing broken parts or swapping out payloads, could double their lifetimes!

A very interesting point that the study brought up is related to the legal aspects of producing in space – who is responsible if there is an incident during production? Any accident could lead to the proliferation of new space junk. This needs further exploration.

In the third study, Airbus investigated a preliminary design of an on-orbit servicing station for satellite manufacturing, refurbishing and recycling.

Starting from studying current missions and projects under development or foreseen for on-orbit servicing, the team created seven potential scenarios which were assessed based on five criteria: technology complexity, market trend, timeframe, business impact and sustainability impact. As a result, two scenarios were retained for the following steps of the study.

First scenario looked at an autonomous on-orbit assembly and payload refurbishment for large constellation in LEO while the second explored a versatile on-orbit servicing station (OSS) for Geo S/C, from telecommunication GeoHub to Cloud S/C. The later was expanded into a preliminary design of the space assets required to perform in-orbit manufacturing, testing and integration of large equipment for Customer satellites in geostationary orbit.

The study concludes that platform and support technologies can be developed with a relatively low risk/good confidence in the outcome, duration and cost, due to either being based on extensive heritage (platform equipment) or requiring moderate evolutions based on existing technologies. On the other hand, in-orbit manufacturing technologies (materials and processes) are still in their infancy and their feasibility is uncertain, especially when it comes to additive manufacturing of metals and liquid glues, which suffer from outgassing and require long curation time.

Last but not least, Airbus explored the prospect of manufacturing large antennas in space.

The team chose two use cases: a 20-metre high-frequency antenna operating in geostationary orbit, and a 30-metre, low-frequency antenna operating in low-Earth orbit.

Our current methods for manufacturing antennas on Earth are not suitable for in-orbit manufacturing, so Airbus investigated new processes and materials that could be used to build in space. They came up with a design that they called a ‘brick reflector’, which consists of hundreds of individual bricks manufactured on Earth assembled in space into an antenna using a robotic arm.

Using such a ‘space factory’ to build structures in space could help us build much bigger, lighter and more complex structures. But it comes at a cost, and it would be important to figure out how to control the quality of objects made in space.

Preparation studies

Meanwhile, a set of four studies funded by the Preparation element of ESA’s Basic Activities considered the future of in-orbit servicing in preparation for the ESA’s 2022 Ministerial Council. In each study, a European industry partner outlined their vision for Europe’s first in-orbit servicing mission, to be launched at the latest by 2028.

Read more about these studies in our dedicated article. Due to their success, ESA allocated further funding to implement one or possibly even two of the four proposed missions.

What else is ESA doing?

In-orbit servicing is already in action on board the International Space Station (ISS), of which ESA is a key partner. Since construction began in 1998, the station has been built up to adapt it to our changing needs, as well as being refuelled dozens of times. Lessons learned from the ISS are now being applied to the space Gateway, which includes a European Refuelling Module that provides fuel to the Gateway’s propulsion system.

More fundamental technical developments are also being undertaken by European engineers. Over the last decade, ESA has developed 3D printing in microgravity conditions, a process that will be key for in-orbit manufacturing. ESA installed Europe’s very first 3D printer in space on board the International Space Station in 2015. Plastic parts printed on the ISS were then compared with otherwise identical parts printed on the ground.

In 2020 the Manufacturing of Experimental Layer Technology (MELT) project supported through ESA’S Technology Development Element presented Europe’s first 3D printer designed for use in weightlessness, printing aerospace-quality plastics. The MELT printer can even print high-melting point thermoplastics such as PEEK, which is robust enough to substitute for metal materials in some cases.

The newer IMPERIAL 3D printer, designed by a Europe-wide industrial consortium, can print high performance polymer parts of unlimited size along one direction.

In July 2022, ESA ran an In-Orbit Service Manufacturing workshop, which focused on understanding what in-orbit servicing and manufacturing is and where Europe would like to go with it. The next step will be to establish a pan-European working group to further define what is needed to position Europe as a leader in the field, and promote the capabilities offered by ESA Member States.

Meanwhile, ESA’s Clean Space initiative is exploring the concept of a multi-purpose Space Servicing Vehicle. This ‘Swiss Army knife’ of a satellite would have the agility, capability and autonomy to perform all kinds of complex tasks in space, such as refuelling high-value satellites reaching the end of their lives, adding new equipment to them, or moving them to new orbits.

What are other space agencies and companies doing?

Over the last few years, many space agencies have become interested in manufacturing, assembling, recycling and refurbishing satellites in space.

In 2020, the Chinese Journal of Aeronautics published a review of in-space assembly technologies, looking in particular at the development status of autonomous robot assembly around the world, and providing future development trends and potential applications. Also in 2020, China Academy of Space Technology reported the first demonstration of on-orbit additive manufacturing of carbon fibre thermoplastic composite materials.

JAXA, meanwhile, has started working with Astroscale Japan on a concept for a satellite refuelling service.

NASA is actively exploring the potential to service, assemble and manufacture satellites in space through a number of projects. From robotic refuelling missions to a dedicated servicing spacecraft through a telescope assembled in space, a list can be found on this page.

In February 2020, Northrop Grumman’s Mission Extension Vehicle-1 (MEV-1) docked to telecommunications satellite Intelsat 901, extending the satellite’s lifetime by five years. The in-space manoeuvre was the first time two commercial satellites docked, and the first time that mission extension services were offered to a satellite in geosynchronous orbit. In April 2021, MEV-2 docked with Intelsat 10-02 to extend its lifetime by five years. Going further, SpaceLogistics (a Northtrop Grumman company) is also proposing to extend the lifetime of GEO satellites through its Mission Extension Pods (MEP) which would be small, customer-owned, customer-controlled propulsion augmentation device to be installed by a SpaceLogistics Mission Robotic Vehicle (MRV) on a client satellite already on-orbit and running low on fuel.

As of January 2023, the European Commission has been funding Thales Alenia Space to lead an in-orbit servicing programme called the European Robotic Orbital Support Services In Orbit Demonstrator. This project will validate the technologies needed for robotic in-space servicing operations, culminating in a mission by 2026.

Last updated on 29 April 2024.

Germany

Germany

Austria

Austria

Belgium

Belgium

Denmark

Denmark

Spain

Spain

Estonia

Estonia

Finland

Finland

France

France

Greece

Greece

Hungary

Hungary

Ireland

Ireland

Italy

Italy

Luxembourg

Luxembourg

Norway

Norway

The Netherlands

The Netherlands

Poland

Poland

Portugal

Portugal

Czechia

Czechia

Romania

Romania

United Kingdom

United Kingdom

Slovenia

Slovenia

Sweden

Sweden

Switzerland

Switzerland